freeamfva's blog

Environmental Lights Continuous LED Strip Light

This month, PLSN’s Buyers Guide focuses on LED tape and flexible LED products (See pages 26-27). Once I compiled the list from every manufacturer on what they wished to list, I poked around all the different sites for some more info. If you look at today’s LED tape, there are so many models offered.To get more news about led bar decor, you can visit htj-led.com official website.

Almost all LED tape products had one thing in common: You could see the separate pixels up close. Especially on camera. Even when diffused, hot spots were there. Other companies offer some faux neon alternatives that are great products. But I was searching for something unique and new on the market. I just didn’t know what.

I stopped into the Environmental Lights website and immediately realized that I had found the king of LED tape — and was a little embarrassed about not already being aware of their wide range. They have whole divisions of different styles including RGB and multi-color LED strips, tunable white LED strip lights, white architectural LED strip lights and single-color LED strip lights.

Then there is the matter of UL listing (all of Environmental Lights products are) and IP ratings. Do they offer waterproof as well as indoor models? Are they capable of being stepped on and not broken? What does it take to make them dimmable? Is there a slim model made for getting in tight spaces? Do they have a bright white with a CRI of 95+? Is there a model that can fold at 90° angles easily? The answer is yes, Environmental Lights manufactures a product that can cover every one of these options.

But while browsing, one particular product caught my eye, and I immediately knew I found that unique product I was in search of — the Continuous LED Strip Light. It’s a new style of LED tape that is not all about separation of pixels, but one continuous line of COB that creates a diffused line of light. This eliminates the dots or hot spots users see in standard SMD LED tape.

I called them up and asked for a couple samples to play around with. At the moment, this continuous LED strip light is only available in white, spanning a variety of color temperature models. It is not available in a tunable white model yet, but I’m told that will be available early this summer along with single color versions (and RGB is also in development).

Users can currently choose between 2700K, 3000K, 3500K, 4000K, 5000K and 6500K color temperatures. I was sent sample kits with a 2700K model that had a single amber colored line across a black colored tape as well as a 4000K model that featured a similar amber line centered on white tape. Both of these sample kits came with a 110V-24V power supply mounted to them.

As soon as I plug it in to the 100V wall outlet, they pop to full brightness. I attached them to a stick of truss to see how they looked side by side. When they are off, the black tape was way less noticeable than its white counterpart. But when illuminated at full, the strip with the white background was noticeably brighter, basically because of the extra bounce of light coming from the white tape combined with the higher color temperature and efficacy.

The ambient light glowing from the COB mounted on the white tape made it appear twice as bright to my eye. But in all fairness, the 2700K model emits 1290 lumens per meter compared to the 1410 lumens emitted by the 4000K model.

Luminous efficacy is a measure of how well a light source produces visible light. It is the ratio of luminous flux to power, measured in lumens per watt. (They measure this by multiplying lumens times wattage). So while the input current for all the models of this continuous LED strip light is 3750 mA, the efficacy of the 2700K model is at 71.7, while the 4000K model is running at 90. We also note that the CRI on all the models is 90+, regardless of color temperature.

I was unable to test the dimming just using a conventional dimmer, as LED tape runs on +24 Volts and the sample kit comes with a non-dimming power supply. The simplest option for dimming would be their inline controller, such as the Dim-MiniLine. It has a few simple controls, all of which are accessible by buttons on the dimmer (no remote, programming, etc.). There is a “low speed” dimming option suitable for non-video applications. This is great for basic installations.

Environmental Lights was quick to point out that they offer plenty of DMX-based options if you would like higher speed dimming (suitable for on-film use), but that requires a more complicated setup with a DMX controller and software. Alternatively, they have a UNV series of universal dimming power supplies. They will work with (essentially) any conventional 120V dimmer as well as 0-10V. Heck, they also have a convenient 0-10V knob that can stand in for a dimmer.

Each reel comes in a 5 meter length with an option to buy additional one-foot lengths if you just need a little bit to finish a project. The width of the tape is 10mm, a little over a third of an inch. Each length utilizes 90 watts, meaning it utilizes .75 amps of current at 120V. Of course, each section of the continuous LED strip can be cut into smaller sections to make it fit anywhere. The tape has cutting marks every 1.54 inches.

I stopped into the Environmental Lights website and immediately realized that I had found the king of LED tape — and was a little embarrassed about not already being aware of their wide range. They have whole divisions of different styles including RGB and multi-color LED strips, tunable white LED strip lights, white architectural LED strip lights and single-color LED strip lights.

Then there is the matter of UL listing (all of Environmental Lights products are) and IP ratings. Do they offer waterproof as well as indoor models? Are they capable of being stepped on and not broken? What does it take to make them dimmable? Is there a slim model made for getting in tight spaces? Do they have a bright white with a CRI of 95+? Is there a model that can fold at 90° angles easily? The answer is yes, Environmental Lights manufactures a product that can cover every one of these options.

But while browsing, one particular product caught my eye, and I immediately knew I found that unique product I was in search of — the Continuous LED Strip Light. It’s a new style of LED tape that is not all about separation of pixels, but one continuous line of COB that creates a diffused line of light. This eliminates the dots or hot spots users see in standard SMD LED tape.

I called them up and asked for a couple samples to play around with. At the moment, this continuous LED strip light is only available in white, spanning a variety of color temperature models. It is not available in a tunable white model yet, but I’m told that will be available early this summer along with single color versions (and RGB is also in development).

Users can currently choose between 2700K, 3000K, 3500K, 4000K, 5000K and 6500K color temperatures. I was sent sample kits with a 2700K model that had a single amber colored line across a black colored tape as well as a 4000K model that featured a similar amber line centered on white tape. Both of these sample kits came with a 110V-24V power supply mounted to them.

As soon as I plug it in to the 100V wall outlet, they pop to full brightness. I attached them to a stick of truss to see how they looked side by side. When they are off, the black tape was way less noticeable than its white counterpart. But when illuminated at full, the strip with the white background was noticeably brighter, basically because of the extra bounce of light coming from the white tape combined with the higher color temperature and efficacy.

The ambient light glowing from the COB mounted on the white tape made it appear twice as bright to my eye. But in all fairness, the 2700K model emits 1290 lumens per meter compared to the 1410 lumens emitted by the 4000K model.

Luminous efficacy is a measure of how well a light source produces visible light. It is the ratio of luminous flux to power, measured in lumens per watt. (They measure this by multiplying lumens times wattage). So while the input current for all the models of this continuous LED strip light is 3750 mA, the efficacy of the 2700K model is at 71.7, while the 4000K model is running at 90. We also note that the CRI on all the models is 90+, regardless of color temperature.

I was unable to test the dimming just using a conventional dimmer, as LED tape runs on +24 Volts and the sample kit comes with a non-dimming power supply. The simplest option for dimming would be their inline controller, such as the Dim-MiniLine. It has a few simple controls, all of which are accessible by buttons on the dimmer (no remote, programming, etc.). There is a “low speed” dimming option suitable for non-video applications. This is great for basic installations.

Environmental Lights was quick to point out that they offer plenty of DMX-based options if you would like higher speed dimming (suitable for on-film use), but that requires a more complicated setup with a DMX controller and software. Alternatively, they have a UNV series of universal dimming power supplies. They will work with (essentially) any conventional 120V dimmer as well as 0-10V. Heck, they also have a convenient 0-10V knob that can stand in for a dimmer.

Each reel comes in a 5 meter length with an option to buy additional one-foot lengths if you just need a little bit to finish a project. The width of the tape is 10mm, a little over a third of an inch. Each length utilizes 90 watts, meaning it utilizes .75 amps of current at 120V. Of course, each section of the continuous LED strip can be cut into smaller sections to make it fit anywhere. The tape has cutting marks every 1.54 inches.

I stopped into the Environmental Lights website and immediately realized that I had found the king of LED tape — and was a little embarrassed about not already being aware of their wide range. They have whole divisions of different styles including RGB and multi-color LED strips, tunable white LED strip lights, white architectural LED strip lights and single-color LED strip lights.

Then there is the matter of UL listing (all of Environmental Lights products are) and IP ratings. Do they offer waterproof as well as indoor models? Are they capable of being stepped on and not broken? What does it take to make them dimmable? Is there a slim model made for getting in tight spaces? Do they have a bright white with a CRI of 95+? Is there a model that can fold at 90° angles easily? The answer is yes, Environmental Lights manufactures a product that can cover every one of these options.

But while browsing, one particular product caught my eye, and I immediately knew I found that unique product I was in search of — the Continuous LED Strip Light. It’s a new style of LED tape that is not all about separation of pixels, but one continuous line of COB that creates a diffused line of light. This eliminates the dots or hot spots users see in standard SMD LED tape.

I called them up and asked for a couple samples to play around with. At the moment, this continuous LED strip light is only available in white, spanning a variety of color temperature models. It is not available in a tunable white model yet, but I’m told that will be available early this summer along with single color versions (and RGB is also in development).

Users can currently choose between 2700K, 3000K, 3500K, 4000K, 5000K and 6500K color temperatures. I was sent sample kits with a 2700K model that had a single amber colored line across a black colored tape as well as a 4000K model that featured a similar amber line centered on white tape. Both of these sample kits came with a 110V-24V power supply mounted to them.

As soon as I plug it in to the 100V wall outlet, they pop to full brightness. I attached them to a stick of truss to see how they looked side by side. When they are off, the black tape was way less noticeable than its white counterpart. But when illuminated at full, the strip with the white background was noticeably brighter, basically because of the extra bounce of light coming from the white tape combined with the higher color temperature and efficacy.

The ambient light glowing from the COB mounted on the white tape made it appear twice as bright to my eye. But in all fairness, the 2700K model emits 1290 lumens per meter compared to the 1410 lumens emitted by the 4000K model.

Luminous efficacy is a measure of how well a light source produces visible light. It is the ratio of luminous flux to power, measured in lumens per watt. (They measure this by multiplying lumens times wattage). So while the input current for all the models of this continuous LED strip light is 3750 mA, the efficacy of the 2700K model is at 71.7, while the 4000K model is running at 90. We also note that the CRI on all the models is 90+, regardless of color temperature.

I was unable to test the dimming just using a conventional dimmer, as LED tape runs on +24 Volts and the sample kit comes with a non-dimming power supply. The simplest option for dimming would be their inline controller, such as the Dim-MiniLine. It has a few simple controls, all of which are accessible by buttons on the dimmer (no remote, programming, etc.). There is a “low speed” dimming option suitable for non-video applications. This is great for basic installations.

Environmental Lights was quick to point out that they offer plenty of DMX-based options if you would like higher speed dimming (suitable for on-film use), but that requires a more complicated setup with a DMX controller and software. Alternatively, they have a UNV series of universal dimming power supplies. They will work with (essentially) any conventional 120V dimmer as well as 0-10V. Heck, they also have a convenient 0-10V knob that can stand in for a dimmer.

Each reel comes in a 5 meter length with an option to buy additional one-foot lengths if you just need a little bit to finish a project. The width of the tape is 10mm, a little over a third of an inch. Each length utilizes 90 watts, meaning it utilizes .75 amps of current at 120V. Of course, each section of the continuous LED strip can be cut into smaller sections to make it fit anywhere. The tape has cutting marks every 1.54 inches.

I stopped into the Environmental Lights website and immediately realized that I had found the king of LED tape — and was a little embarrassed about not already being aware of their wide range. They have whole divisions of different styles including RGB and multi-color LED strips, tunable white LED strip lights, white architectural LED strip lights and single-color LED strip lights.

Then there is the matter of UL listing (all of Environmental Lights products are) and IP ratings. Do they offer waterproof as well as indoor models? Are they capable of being stepped on and not broken? What does it take to make them dimmable? Is there a slim model made for getting in tight spaces? Do they have a bright white with a CRI of 95+? Is there a model that can fold at 90° angles easily? The answer is yes, Environmental Lights manufactures a product that can cover every one of these options.

But while browsing, one particular product caught my eye, and I immediately knew I found that unique product I was in search of — the Continuous LED Strip Light. It’s a new style of LED tape that is not all about separation of pixels, but one continuous line of COB that creates a diffused line of light. This eliminates the dots or hot spots users see in standard SMD LED tape.

I called them up and asked for a couple samples to play around with. At the moment, this continuous LED strip light is only available in white, spanning a variety of color temperature models. It is not available in a tunable white model yet, but I’m told that will be available early this summer along with single color versions (and RGB is also in development).

Users can currently choose between 2700K, 3000K, 3500K, 4000K, 5000K and 6500K color temperatures. I was sent sample kits with a 2700K model that had a single amber colored line across a black colored tape as well as a 4000K model that featured a similar amber line centered on white tape. Both of these sample kits came with a 110V-24V power supply mounted to them.

As soon as I plug it in to the 100V wall outlet, they pop to full brightness. I attached them to a stick of truss to see how they looked side by side. When they are off, the black tape was way less noticeable than its white counterpart. But when illuminated at full, the strip with the white background was noticeably brighter, basically because of the extra bounce of light coming from the white tape combined with the higher color temperature and efficacy.

The ambient light glowing from the COB mounted on the white tape made it appear twice as bright to my eye. But in all fairness, the 2700K model emits 1290 lumens per meter compared to the 1410 lumens emitted by the 4000K model.

Luminous efficacy is a measure of how well a light source produces visible light. It is the ratio of luminous flux to power, measured in lumens per watt. (They measure this by multiplying lumens times wattage). So while the input current for all the models of this continuous LED strip light is 3750 mA, the efficacy of the 2700K model is at 71.7, while the 4000K model is running at 90. We also note that the CRI on all the models is 90+, regardless of color temperature.

I was unable to test the dimming just using a conventional dimmer, as LED tape runs on +24 Volts and the sample kit comes with a non-dimming power supply. The simplest option for dimming would be their inline controller, such as the Dim-MiniLine. It has a few simple controls, all of which are accessible by buttons on the dimmer (no remote, programming, etc.). There is a “low speed” dimming option suitable for non-video applications. This is great for basic installations.

Environmental Lights was quick to point out that they offer plenty of DMX-based options if you would like higher speed dimming (suitable for on-film use), but that requires a more complicated setup with a DMX controller and software. Alternatively, they have a UNV series of universal dimming power supplies. They will work with (essentially) any conventional 120V dimmer as well as 0-10V. Heck, they also have a convenient 0-10V knob that can stand in for a dimmer.

Each reel comes in a 5 meter length with an option to buy additional one-foot lengths if you just need a little bit to finish a project. The width of the tape is 10mm, a little over a third of an inch. Each length utilizes 90 watts, meaning it utilizes .75 amps of current at 120V. Of course, each section of the continuous LED strip can be cut into smaller sections to make it fit anywhere. The tape has cutting marks every 1.54 inches.

Taking care of service members first priority for first aid kit assembly party

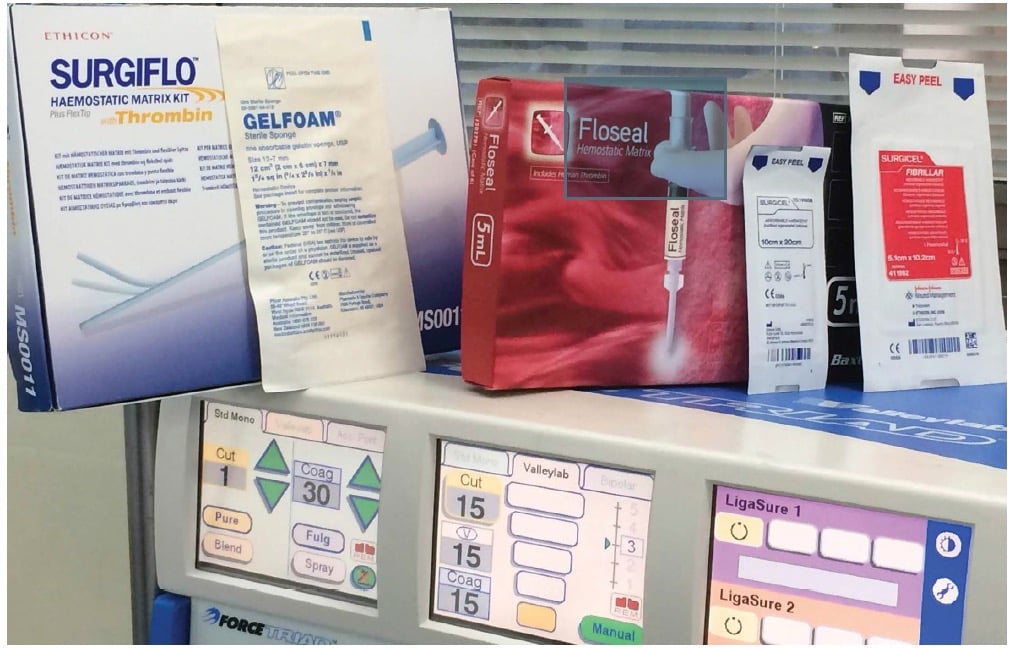

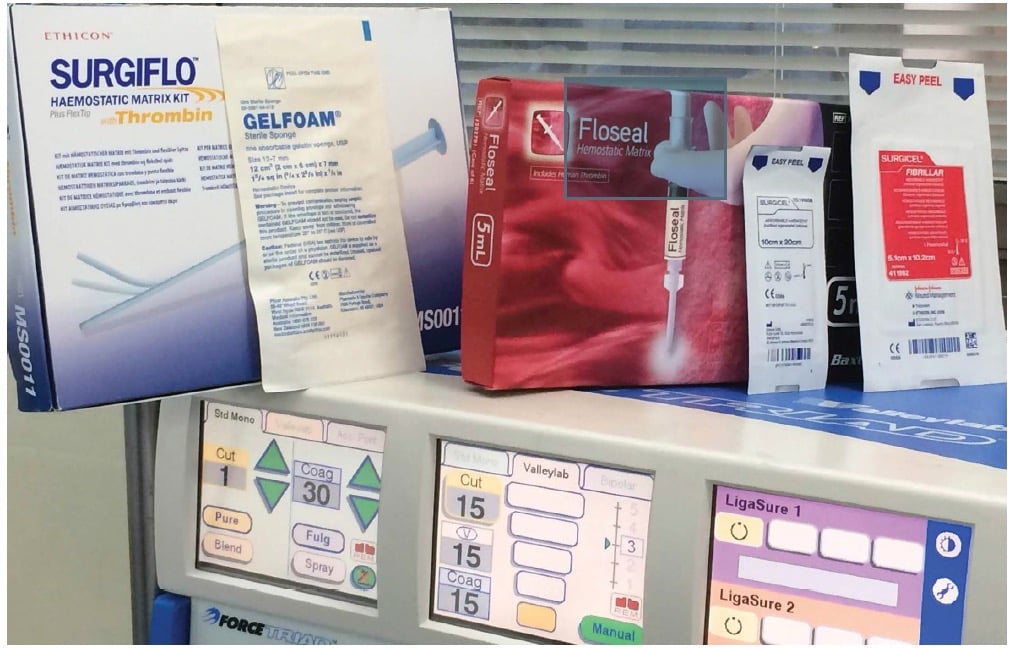

A first aid kit is a critical piece of equipment for service members departing Al Udeid Air Base to support military operations down range.To get more news about chest seal twin pack, you can visit rusuntacmed.com official website.

Warfighters can rest assured knowing that the military family at the base supports them as civilian and military members come together once a month to assemble and certify the first aid kits that are distributed in theater.

More than 70 volunteers attended the June 15 assembly party, and in two and a half hours they helped assemble and recertify about 1,300 first aid kits.

“It’s a really big job, as we’re talking thousands of kits that need to be certified every month. We are the only recertifying facility for the entire area of operations,” said Tech Sgt. Joseph Gill, NCO in charge of warehouse medical logistics for the 379th Expeditionary Medical Support Squadron. “The need for the kits is always there and has been increasing as we’re seeing more people forward deployed.”

Gill added that Team AUAB is also now receiving and assembling the new Joint First Aid Kits for employment down range.

The new JFAK will be used by all services across the Department of Defense and is designed to fit with the Modular Lightweight Load-carrying Equipment-style protective gear. The new kit has a five-year shelf life and has all of its components individually compartmentalized inside. Two tourniquets are attached on the outside of the kit for quick access.

Gill said the new kits need only to be checked, the tourniquets attached and then tagged. To be sure not to mix parts or processes, Gill holds separate assembly parties depending on how many of the new kits are received.

Gill said there was no way his small staff could process the volume of kits required every month on their own.

“If it were not for our volunteers, we simply would not be able to take care of our service members. They [the volunteers] show up every month and pitch in to get the job done,” he said.

The current Air Force-specific Individual First Aid Kits have a shelf-life of three years. The kits have two vacuum-sealed packages with various first aid components. Every month, the kits need to be recertified by replacing items that have expired with newer ones to bring the kits into compliance for another year.

“It is a unique situation here because we are the hub for the entire AOR and we process a huge volume of kits,” said Tech Sgt. Jennifer Lotan, also from the 379th Expeditionary Medical Support Squadron. “I haven’t seen something like this before where so many people come to help out. It’s pretty impressive.”

Staff Sgt. Timothy Byrd, 379th Expeditionary Maintenance Squadron, has attended a couple parties and said he appreciates the community support.

“I’ve been deployed before to Afghanistan and Jordan, so I know the necessity of having a first aid kit on your person,” he said. “I never gave much thought as to how they were put together, so when I heard they needed help in assembling the kits, I was happy to help out.”

Local Command Sponsorship Program military spouses come regularly to the parties, finding it a good way to give back to the community and build relationships with the deployed service members who attend. They also bring home-baked treats to share with all the volunteers.

“It’s a good opportunity to be able to do something to help support the service members,” said Melissa James, spouse of Brig. Gen. Darren James, commander, 379th Air Expeditionary Wing. “We’re a small group of spouses here, and it’s a different situation for us than being stationed stateside. So this is just a wonderful way for us to help out and to meet and talk with the military folks. I love the social aspect of it. It’s a fun time and for a good cause.”

More than 70 volunteers attended the June 15 assembly party, and in two and a half hours they helped assemble and recertify about 1,300 first aid kits.

“It’s a really big job, as we’re talking thousands of kits that need to be certified every month. We are the only recertifying facility for the entire area of operations,” said Tech Sgt. Joseph Gill, NCO in charge of warehouse medical logistics for the 379th Expeditionary Medical Support Squadron. “The need for the kits is always there and has been increasing as we’re seeing more people forward deployed.”

Gill added that Team AUAB is also now receiving and assembling the new Joint First Aid Kits for employment down range.

The new JFAK will be used by all services across the Department of Defense and is designed to fit with the Modular Lightweight Load-carrying Equipment-style protective gear. The new kit has a five-year shelf life and has all of its components individually compartmentalized inside. Two tourniquets are attached on the outside of the kit for quick access.

Gill said the new kits need only to be checked, the tourniquets attached and then tagged. To be sure not to mix parts or processes, Gill holds separate assembly parties depending on how many of the new kits are received.

Gill said there was no way his small staff could process the volume of kits required every month on their own.

“If it were not for our volunteers, we simply would not be able to take care of our service members. They [the volunteers] show up every month and pitch in to get the job done,” he said.

The current Air Force-specific Individual First Aid Kits have a shelf-life of three years. The kits have two vacuum-sealed packages with various first aid components. Every month, the kits need to be recertified by replacing items that have expired with newer ones to bring the kits into compliance for another year.

“It is a unique situation here because we are the hub for the entire AOR and we process a huge volume of kits,” said Tech Sgt. Jennifer Lotan, also from the 379th Expeditionary Medical Support Squadron. “I haven’t seen something like this before where so many people come to help out. It’s pretty impressive.”

Staff Sgt. Timothy Byrd, 379th Expeditionary Maintenance Squadron, has attended a couple parties and said he appreciates the community support.

“I’ve been deployed before to Afghanistan and Jordan, so I know the necessity of having a first aid kit on your person,” he said. “I never gave much thought as to how they were put together, so when I heard they needed help in assembling the kits, I was happy to help out.”

Local Command Sponsorship Program military spouses come regularly to the parties, finding it a good way to give back to the community and build relationships with the deployed service members who attend. They also bring home-baked treats to share with all the volunteers.

“It’s a good opportunity to be able to do something to help support the service members,” said Melissa James, spouse of Brig. Gen. Darren James, commander, 379th Air Expeditionary Wing. “We’re a small group of spouses here, and it’s a different situation for us than being stationed stateside. So this is just a wonderful way for us to help out and to meet and talk with the military folks. I love the social aspect of it. It’s a fun time and for a good cause.”

More than 70 volunteers attended the June 15 assembly party, and in two and a half hours they helped assemble and recertify about 1,300 first aid kits.

“It’s a really big job, as we’re talking thousands of kits that need to be certified every month. We are the only recertifying facility for the entire area of operations,” said Tech Sgt. Joseph Gill, NCO in charge of warehouse medical logistics for the 379th Expeditionary Medical Support Squadron. “The need for the kits is always there and has been increasing as we’re seeing more people forward deployed.”

Gill added that Team AUAB is also now receiving and assembling the new Joint First Aid Kits for employment down range.

The new JFAK will be used by all services across the Department of Defense and is designed to fit with the Modular Lightweight Load-carrying Equipment-style protective gear. The new kit has a five-year shelf life and has all of its components individually compartmentalized inside. Two tourniquets are attached on the outside of the kit for quick access.

Gill said the new kits need only to be checked, the tourniquets attached and then tagged. To be sure not to mix parts or processes, Gill holds separate assembly parties depending on how many of the new kits are received.

Gill said there was no way his small staff could process the volume of kits required every month on their own.

“If it were not for our volunteers, we simply would not be able to take care of our service members. They [the volunteers] show up every month and pitch in to get the job done,” he said.

The current Air Force-specific Individual First Aid Kits have a shelf-life of three years. The kits have two vacuum-sealed packages with various first aid components. Every month, the kits need to be recertified by replacing items that have expired with newer ones to bring the kits into compliance for another year.

“It is a unique situation here because we are the hub for the entire AOR and we process a huge volume of kits,” said Tech Sgt. Jennifer Lotan, also from the 379th Expeditionary Medical Support Squadron. “I haven’t seen something like this before where so many people come to help out. It’s pretty impressive.”

Staff Sgt. Timothy Byrd, 379th Expeditionary Maintenance Squadron, has attended a couple parties and said he appreciates the community support.

“I’ve been deployed before to Afghanistan and Jordan, so I know the necessity of having a first aid kit on your person,” he said. “I never gave much thought as to how they were put together, so when I heard they needed help in assembling the kits, I was happy to help out.”

Local Command Sponsorship Program military spouses come regularly to the parties, finding it a good way to give back to the community and build relationships with the deployed service members who attend. They also bring home-baked treats to share with all the volunteers.

“It’s a good opportunity to be able to do something to help support the service members,” said Melissa James, spouse of Brig. Gen. Darren James, commander, 379th Air Expeditionary Wing. “We’re a small group of spouses here, and it’s a different situation for us than being stationed stateside. So this is just a wonderful way for us to help out and to meet and talk with the military folks. I love the social aspect of it. It’s a fun time and for a good cause.”

More than 70 volunteers attended the June 15 assembly party, and in two and a half hours they helped assemble and recertify about 1,300 first aid kits.

“It’s a really big job, as we’re talking thousands of kits that need to be certified every month. We are the only recertifying facility for the entire area of operations,” said Tech Sgt. Joseph Gill, NCO in charge of warehouse medical logistics for the 379th Expeditionary Medical Support Squadron. “The need for the kits is always there and has been increasing as we’re seeing more people forward deployed.”

Gill added that Team AUAB is also now receiving and assembling the new Joint First Aid Kits for employment down range.

The new JFAK will be used by all services across the Department of Defense and is designed to fit with the Modular Lightweight Load-carrying Equipment-style protective gear. The new kit has a five-year shelf life and has all of its components individually compartmentalized inside. Two tourniquets are attached on the outside of the kit for quick access.

Gill said the new kits need only to be checked, the tourniquets attached and then tagged. To be sure not to mix parts or processes, Gill holds separate assembly parties depending on how many of the new kits are received.

Gill said there was no way his small staff could process the volume of kits required every month on their own.

“If it were not for our volunteers, we simply would not be able to take care of our service members. They [the volunteers] show up every month and pitch in to get the job done,” he said.

The current Air Force-specific Individual First Aid Kits have a shelf-life of three years. The kits have two vacuum-sealed packages with various first aid components. Every month, the kits need to be recertified by replacing items that have expired with newer ones to bring the kits into compliance for another year.

“It is a unique situation here because we are the hub for the entire AOR and we process a huge volume of kits,” said Tech Sgt. Jennifer Lotan, also from the 379th Expeditionary Medical Support Squadron. “I haven’t seen something like this before where so many people come to help out. It’s pretty impressive.”

Staff Sgt. Timothy Byrd, 379th Expeditionary Maintenance Squadron, has attended a couple parties and said he appreciates the community support.

“I’ve been deployed before to Afghanistan and Jordan, so I know the necessity of having a first aid kit on your person,” he said. “I never gave much thought as to how they were put together, so when I heard they needed help in assembling the kits, I was happy to help out.”

Local Command Sponsorship Program military spouses come regularly to the parties, finding it a good way to give back to the community and build relationships with the deployed service members who attend. They also bring home-baked treats to share with all the volunteers.

“It’s a good opportunity to be able to do something to help support the service members,” said Melissa James, spouse of Brig. Gen. Darren James, commander, 379th Air Expeditionary Wing. “We’re a small group of spouses here, and it’s a different situation for us than being stationed stateside. So this is just a wonderful way for us to help out and to meet and talk with the military folks. I love the social aspect of it. It’s a fun time and for a good cause.”

MAKING THE MOST OF PROGRESSING CAVITY PUMPS IN DIFFICULT FOOD AND BEVERAGE APPLICATIONS

While progressing cavity pumps are not the most commonly used option for conveyance in food and beverage production, they are required for certain applications, including those requiring very gentle handling or continuous non-pulsing flow, or for conveying highly viscous media. Progressing cavity pumps can be well-suited to food and beverage applications’ essentials regarding contamination avoidance. With the right system design, progressing cavity pumps can reduce cost, lower maintenance needs, and achieve better results in complex conveying applications within food and beverage production.To get more news about Progressive cavity pump stator, you can visit brysonpump.com official website.

Where food and beverage pumping applications are concerned, progressing cavity pumps are rarely the first thought in system design. Rotary lobe and centrifugal pumps are far more commonly used in these applications, and indeed are often the right choice. In many situations, however, rotary lobe and centrifugal pumps are not up to the task of conveyance in food and beverage applications, or are not the most cost-effective solution.

NETZSCH PumpsProgressing cavity pumps can handle higher pressures and higher viscosity materials than either rotary lobe or centrifugal pumps. Cost savings of up to 50 percent are possible with progressing cavity pumps over rotary lobe pumps, especially in smaller volume operations. The progressive cavity technology can also be designed with an open hopper that allows for the pumping of non-flowing products such as meats and vegetables. The choice in not so clear-cut for applications requiring an extremely small footprint; in these cases, designers must balance the need for the benefits achieved by use of progressing cavity pumps with available space to determine the best solution.

In the end, progressing cavity pumps are ideal for conveyance tasks in a number of food and beverage production environments, especially those with difficult-to-convey, shear-sensitive, abrasive, and/or viscous components. The pumping process in progressing cavity pumps involves a rotor turning with an eccentric rotary motion within a fixed stator. The two components are precisely geometrically mated with one another, conveying chambers are formed between them, and these chambers advance during rotation. The medium is gently transported in these chambers from the inlet to the discharge side by the turning motion. Volume and pressure remain constant with progressing cavity pump technology, regardless of the viscosity or consistency of the substance being conveyed. In addition, no shear forces, pulsation, or pressure reversal points occur, thus avoiding damage to the medium.

In food and beverage applications specifically, progressing cavity pumps must be designed to reduce the risk of contamination and help achieve the targets of the Food and Drug Administration’s (FDA’s) Food Safety Modernization Act (FSMA). To do so, pumps must use FDA- compliant materials, including metals, plastics, and elastomers, with each elastomer compound independently tested to determine suitability and be of a high hygienic design. Depending on the process and the industry, 3-A Sanitary Standards Inc. (3-A SSI) or European Hygienic Engineering and Design Group (EHEDG) certification may be required for pump systems and processes in food and beverage applications.

Making CIP work in PC/PD pumps

NETZSCH PumpsCIP procedures are critically important in food and beverage conveying applications because proper pump and pipe cleaning is key to avoiding contamination, bacterial growth, and other issues. By running a cleaning agent (acids and caustics) through the pump system, proper cleaning can be ensured and regulatory requirements met. It is important therefore to utilize the cleanest possible design within the pump to minimize cleaning time and maximize production time. A well designed CIP system can even be used to CIP open hopper pumps after pumping non flowing products.

Benefits of well-designed pumping technology

It is important to take cleaning into account when first designing the pumping system. The progressing cavity pump rotor should be designed to be compatible with both the process’s media and temperature range and the chemicals being used in the CIP process and their temperature. CIP processes can change, and when they do, compatibility with the stator elastomer should be verified and the stator or cleaning solution replaced if necessary.

Because a separate dedicated pump is used for CIP (usually a small low-cost centrifugal pump), progressing cavity pump design should include the appropriate bypass setup, to ensure that turbulent flow is achieved in both the pump and the piping downstream of the pump. The NETZSCH NEMO® Progressing Cavity Pump is a good example of this kind of design for sanitary applications. With suction and discharge ports located tangential to the body of the pump, the NEMO pumps achieve complete drainage and proper circulation through the pump for cleaning. In addition, NEMO pumps feature open hygienic joints to enable the best cleaning of the joint and the elimination of dead zones that can lead to contamination. NETZSCH with their NEMO Sanitary Plus design also offers flexible connecting rods in lieu of joints, negating any crevices and reducing CIP time even further.

NETZSCH PumpsProgressing cavity pumps can handle higher pressures and higher viscosity materials than either rotary lobe or centrifugal pumps. Cost savings of up to 50 percent are possible with progressing cavity pumps over rotary lobe pumps, especially in smaller volume operations. The progressive cavity technology can also be designed with an open hopper that allows for the pumping of non-flowing products such as meats and vegetables. The choice in not so clear-cut for applications requiring an extremely small footprint; in these cases, designers must balance the need for the benefits achieved by use of progressing cavity pumps with available space to determine the best solution.

In the end, progressing cavity pumps are ideal for conveyance tasks in a number of food and beverage production environments, especially those with difficult-to-convey, shear-sensitive, abrasive, and/or viscous components. The pumping process in progressing cavity pumps involves a rotor turning with an eccentric rotary motion within a fixed stator. The two components are precisely geometrically mated with one another, conveying chambers are formed between them, and these chambers advance during rotation. The medium is gently transported in these chambers from the inlet to the discharge side by the turning motion. Volume and pressure remain constant with progressing cavity pump technology, regardless of the viscosity or consistency of the substance being conveyed. In addition, no shear forces, pulsation, or pressure reversal points occur, thus avoiding damage to the medium.

In food and beverage applications specifically, progressing cavity pumps must be designed to reduce the risk of contamination and help achieve the targets of the Food and Drug Administration’s (FDA’s) Food Safety Modernization Act (FSMA). To do so, pumps must use FDA- compliant materials, including metals, plastics, and elastomers, with each elastomer compound independently tested to determine suitability and be of a high hygienic design. Depending on the process and the industry, 3-A Sanitary Standards Inc. (3-A SSI) or European Hygienic Engineering and Design Group (EHEDG) certification may be required for pump systems and processes in food and beverage applications.

Making CIP work in PC/PD pumps

NETZSCH PumpsCIP procedures are critically important in food and beverage conveying applications because proper pump and pipe cleaning is key to avoiding contamination, bacterial growth, and other issues. By running a cleaning agent (acids and caustics) through the pump system, proper cleaning can be ensured and regulatory requirements met. It is important therefore to utilize the cleanest possible design within the pump to minimize cleaning time and maximize production time. A well designed CIP system can even be used to CIP open hopper pumps after pumping non flowing products.

Benefits of well-designed pumping technology

It is important to take cleaning into account when first designing the pumping system. The progressing cavity pump rotor should be designed to be compatible with both the process’s media and temperature range and the chemicals being used in the CIP process and their temperature. CIP processes can change, and when they do, compatibility with the stator elastomer should be verified and the stator or cleaning solution replaced if necessary.

Because a separate dedicated pump is used for CIP (usually a small low-cost centrifugal pump), progressing cavity pump design should include the appropriate bypass setup, to ensure that turbulent flow is achieved in both the pump and the piping downstream of the pump. The NETZSCH NEMO® Progressing Cavity Pump is a good example of this kind of design for sanitary applications. With suction and discharge ports located tangential to the body of the pump, the NEMO pumps achieve complete drainage and proper circulation through the pump for cleaning. In addition, NEMO pumps feature open hygienic joints to enable the best cleaning of the joint and the elimination of dead zones that can lead to contamination. NETZSCH with their NEMO Sanitary Plus design also offers flexible connecting rods in lieu of joints, negating any crevices and reducing CIP time even further.

NETZSCH PumpsProgressing cavity pumps can handle higher pressures and higher viscosity materials than either rotary lobe or centrifugal pumps. Cost savings of up to 50 percent are possible with progressing cavity pumps over rotary lobe pumps, especially in smaller volume operations. The progressive cavity technology can also be designed with an open hopper that allows for the pumping of non-flowing products such as meats and vegetables. The choice in not so clear-cut for applications requiring an extremely small footprint; in these cases, designers must balance the need for the benefits achieved by use of progressing cavity pumps with available space to determine the best solution.

In the end, progressing cavity pumps are ideal for conveyance tasks in a number of food and beverage production environments, especially those with difficult-to-convey, shear-sensitive, abrasive, and/or viscous components. The pumping process in progressing cavity pumps involves a rotor turning with an eccentric rotary motion within a fixed stator. The two components are precisely geometrically mated with one another, conveying chambers are formed between them, and these chambers advance during rotation. The medium is gently transported in these chambers from the inlet to the discharge side by the turning motion. Volume and pressure remain constant with progressing cavity pump technology, regardless of the viscosity or consistency of the substance being conveyed. In addition, no shear forces, pulsation, or pressure reversal points occur, thus avoiding damage to the medium.

In food and beverage applications specifically, progressing cavity pumps must be designed to reduce the risk of contamination and help achieve the targets of the Food and Drug Administration’s (FDA’s) Food Safety Modernization Act (FSMA). To do so, pumps must use FDA- compliant materials, including metals, plastics, and elastomers, with each elastomer compound independently tested to determine suitability and be of a high hygienic design. Depending on the process and the industry, 3-A Sanitary Standards Inc. (3-A SSI) or European Hygienic Engineering and Design Group (EHEDG) certification may be required for pump systems and processes in food and beverage applications.

Making CIP work in PC/PD pumps

NETZSCH PumpsCIP procedures are critically important in food and beverage conveying applications because proper pump and pipe cleaning is key to avoiding contamination, bacterial growth, and other issues. By running a cleaning agent (acids and caustics) through the pump system, proper cleaning can be ensured and regulatory requirements met. It is important therefore to utilize the cleanest possible design within the pump to minimize cleaning time and maximize production time. A well designed CIP system can even be used to CIP open hopper pumps after pumping non flowing products.

Benefits of well-designed pumping technology

It is important to take cleaning into account when first designing the pumping system. The progressing cavity pump rotor should be designed to be compatible with both the process’s media and temperature range and the chemicals being used in the CIP process and their temperature. CIP processes can change, and when they do, compatibility with the stator elastomer should be verified and the stator or cleaning solution replaced if necessary.

Because a separate dedicated pump is used for CIP (usually a small low-cost centrifugal pump), progressing cavity pump design should include the appropriate bypass setup, to ensure that turbulent flow is achieved in both the pump and the piping downstream of the pump. The NETZSCH NEMO® Progressing Cavity Pump is a good example of this kind of design for sanitary applications. With suction and discharge ports located tangential to the body of the pump, the NEMO pumps achieve complete drainage and proper circulation through the pump for cleaning. In addition, NEMO pumps feature open hygienic joints to enable the best cleaning of the joint and the elimination of dead zones that can lead to contamination. NETZSCH with their NEMO Sanitary Plus design also offers flexible connecting rods in lieu of joints, negating any crevices and reducing CIP time even further.

NETZSCH PumpsProgressing cavity pumps can handle higher pressures and higher viscosity materials than either rotary lobe or centrifugal pumps. Cost savings of up to 50 percent are possible with progressing cavity pumps over rotary lobe pumps, especially in smaller volume operations. The progressive cavity technology can also be designed with an open hopper that allows for the pumping of non-flowing products such as meats and vegetables. The choice in not so clear-cut for applications requiring an extremely small footprint; in these cases, designers must balance the need for the benefits achieved by use of progressing cavity pumps with available space to determine the best solution.

In the end, progressing cavity pumps are ideal for conveyance tasks in a number of food and beverage production environments, especially those with difficult-to-convey, shear-sensitive, abrasive, and/or viscous components. The pumping process in progressing cavity pumps involves a rotor turning with an eccentric rotary motion within a fixed stator. The two components are precisely geometrically mated with one another, conveying chambers are formed between them, and these chambers advance during rotation. The medium is gently transported in these chambers from the inlet to the discharge side by the turning motion. Volume and pressure remain constant with progressing cavity pump technology, regardless of the viscosity or consistency of the substance being conveyed. In addition, no shear forces, pulsation, or pressure reversal points occur, thus avoiding damage to the medium.

In food and beverage applications specifically, progressing cavity pumps must be designed to reduce the risk of contamination and help achieve the targets of the Food and Drug Administration’s (FDA’s) Food Safety Modernization Act (FSMA). To do so, pumps must use FDA- compliant materials, including metals, plastics, and elastomers, with each elastomer compound independently tested to determine suitability and be of a high hygienic design. Depending on the process and the industry, 3-A Sanitary Standards Inc. (3-A SSI) or European Hygienic Engineering and Design Group (EHEDG) certification may be required for pump systems and processes in food and beverage applications.

Making CIP work in PC/PD pumps

NETZSCH PumpsCIP procedures are critically important in food and beverage conveying applications because proper pump and pipe cleaning is key to avoiding contamination, bacterial growth, and other issues. By running a cleaning agent (acids and caustics) through the pump system, proper cleaning can be ensured and regulatory requirements met. It is important therefore to utilize the cleanest possible design within the pump to minimize cleaning time and maximize production time. A well designed CIP system can even be used to CIP open hopper pumps after pumping non flowing products.

Benefits of well-designed pumping technology

It is important to take cleaning into account when first designing the pumping system. The progressing cavity pump rotor should be designed to be compatible with both the process’s media and temperature range and the chemicals being used in the CIP process and their temperature. CIP processes can change, and when they do, compatibility with the stator elastomer should be verified and the stator or cleaning solution replaced if necessary.

Because a separate dedicated pump is used for CIP (usually a small low-cost centrifugal pump), progressing cavity pump design should include the appropriate bypass setup, to ensure that turbulent flow is achieved in both the pump and the piping downstream of the pump. The NETZSCH NEMO® Progressing Cavity Pump is a good example of this kind of design for sanitary applications. With suction and discharge ports located tangential to the body of the pump, the NEMO pumps achieve complete drainage and proper circulation through the pump for cleaning. In addition, NEMO pumps feature open hygienic joints to enable the best cleaning of the joint and the elimination of dead zones that can lead to contamination. NETZSCH with their NEMO Sanitary Plus design also offers flexible connecting rods in lieu of joints, negating any crevices and reducing CIP time even further.

NEMO Multiphase Progressing Cavity Pump

In the past, many oil fields were no longer considered profitable due to unpredictable flow rates. Using multiphase pumps, oil and gas production remains profitable even when the water or sand content in the medium increases. Thanks to the pumping principle, neither space-intensive separation devices at the well nor separate pumps, compressors and lines are necessary to transport gas and liquid to the central collection stations. Multiphase pumps allow you to pump without initial phase separation. In addition, by using the pumps, you conserve natural resources and thus the environment. To get more news about Progressive cavity pump parts, you can visit brysonpump.com official website.

Due to the closed system and the few existing leakage points, flaring in fields is prevented. The highest standards for equipment and safety are an essential requirement for working in oil fields to keep processes safe and reliable. NEMO® pumps contribute to this safety and reliability. The complexity of the pumped media ranges from high viscosity to low viscosity, from shear sensitive to heavily loaded with solids. The innovative and reliable design allows for efficient process control. These multiphase pumps meet the requirements of API 676 3rd Edition and also those of NACE MR-0-175. Safe and reliable pumping with maximum efficiency, NEMO® Multiphase progressing cavity pumps make it possible.

Due to the closed system and the few existing leakage points, flaring in fields is prevented. The highest standards for equipment and safety are an essential requirement for working in oil fields to keep processes safe and reliable. NEMO® pumps contribute to this safety and reliability. The complexity of the pumped media ranges from high viscosity to low viscosity, from shear sensitive to heavily loaded with solids. The innovative and reliable design allows for efficient process control. These multiphase pumps meet the requirements of API 676 3rd Edition and also those of NACE MR-0-175. Safe and reliable pumping with maximum efficiency, NEMO® Multiphase progressing cavity pumps make it possible.

Due to the closed system and the few existing leakage points, flaring in fields is prevented. The highest standards for equipment and safety are an essential requirement for working in oil fields to keep processes safe and reliable. NEMO® pumps contribute to this safety and reliability. The complexity of the pumped media ranges from high viscosity to low viscosity, from shear sensitive to heavily loaded with solids. The innovative and reliable design allows for efficient process control. These multiphase pumps meet the requirements of API 676 3rd Edition and also those of NACE MR-0-175. Safe and reliable pumping with maximum efficiency, NEMO® Multiphase progressing cavity pumps make it possible.

Due to the closed system and the few existing leakage points, flaring in fields is prevented. The highest standards for equipment and safety are an essential requirement for working in oil fields to keep processes safe and reliable. NEMO® pumps contribute to this safety and reliability. The complexity of the pumped media ranges from high viscosity to low viscosity, from shear sensitive to heavily loaded with solids. The innovative and reliable design allows for efficient process control. These multiphase pumps meet the requirements of API 676 3rd Edition and also those of NACE MR-0-175. Safe and reliable pumping with maximum efficiency, NEMO® Multiphase progressing cavity pumps make it possible.

NEW ALFA LAVAL TWIN SCREW PUMP: TOP FEATURES AND FUNCTIONS

Envision yourself cruising down the highway in a brand-new sports car on a moonlit summer night. Next, picture yourself behind the wheel of a powerful snow plow on a blustery winter day. Both of these vehicles are excellent when used in specific conditions and for distinct purposes.To get more news about SEEPEX Pump Part, you can visit hw-screwpump.com official website.

But what if a single piece of machinery could combine both rugged durability and smooth, agile productivity? As fate would have it, this type of versatility and precision actually exists, and it is embodied by the new Alfa Laval Twin Screw Pump.

TOP FEATURES AND FUNCTIONS:

What all can the versatile Twin Screw Pump do? Take a closer look at a few of its stand-out capabilities and learn why many food/beverage producers are buzzing about it.

THE FLEXIBILITY OF TWIN SCREW TECHNOLOGY

Although classified as a positive displacement pump, Alfa Laval’s Twin Screw can accomplish so much more. Unlike conventional positive displacement pumps which are primarily used for thick, viscous products, the new Twin Screw by Alfa Laval also has the ability to propel thin material like a centrifugal pump.

Gentle and virtually pulse-free, the Twin Screw is able to convey product through at various speeds for different viscosity liquids. This allows the pump to be utilized in a flexible manner within your production, adding significant value to producers with diverse ingredients, such as:

The Alfa Laval Twin Screw Pump is finely crafted with a hygienic, stainless-steel frame, profiled elastomers, and mechanical seals. Utilizing a robust gearbox design, the pump is calibrated to operate quietly, efficiently, and at a reduced temperature to enhance safety.

There are also very few wear items on the pump. Alfa Laval’s Twin Screw has the ability to run for a very long time and requires very little maintenance.

When maintenance is needed, there are plenty of reasons to appreciate this pump. Alfa Laval’s diligent design provides true front-loading access to the pump’s seal and timing gears for easy servicing.

But what if a single piece of machinery could combine both rugged durability and smooth, agile productivity? As fate would have it, this type of versatility and precision actually exists, and it is embodied by the new Alfa Laval Twin Screw Pump.

TOP FEATURES AND FUNCTIONS:

What all can the versatile Twin Screw Pump do? Take a closer look at a few of its stand-out capabilities and learn why many food/beverage producers are buzzing about it.

THE FLEXIBILITY OF TWIN SCREW TECHNOLOGY

Although classified as a positive displacement pump, Alfa Laval’s Twin Screw can accomplish so much more. Unlike conventional positive displacement pumps which are primarily used for thick, viscous products, the new Twin Screw by Alfa Laval also has the ability to propel thin material like a centrifugal pump.

Gentle and virtually pulse-free, the Twin Screw is able to convey product through at various speeds for different viscosity liquids. This allows the pump to be utilized in a flexible manner within your production, adding significant value to producers with diverse ingredients, such as:

The Alfa Laval Twin Screw Pump is finely crafted with a hygienic, stainless-steel frame, profiled elastomers, and mechanical seals. Utilizing a robust gearbox design, the pump is calibrated to operate quietly, efficiently, and at a reduced temperature to enhance safety.

There are also very few wear items on the pump. Alfa Laval’s Twin Screw has the ability to run for a very long time and requires very little maintenance.

When maintenance is needed, there are plenty of reasons to appreciate this pump. Alfa Laval’s diligent design provides true front-loading access to the pump’s seal and timing gears for easy servicing.

But what if a single piece of machinery could combine both rugged durability and smooth, agile productivity? As fate would have it, this type of versatility and precision actually exists, and it is embodied by the new Alfa Laval Twin Screw Pump.

TOP FEATURES AND FUNCTIONS:

What all can the versatile Twin Screw Pump do? Take a closer look at a few of its stand-out capabilities and learn why many food/beverage producers are buzzing about it.

THE FLEXIBILITY OF TWIN SCREW TECHNOLOGY

Although classified as a positive displacement pump, Alfa Laval’s Twin Screw can accomplish so much more. Unlike conventional positive displacement pumps which are primarily used for thick, viscous products, the new Twin Screw by Alfa Laval also has the ability to propel thin material like a centrifugal pump.

Gentle and virtually pulse-free, the Twin Screw is able to convey product through at various speeds for different viscosity liquids. This allows the pump to be utilized in a flexible manner within your production, adding significant value to producers with diverse ingredients, such as:

The Alfa Laval Twin Screw Pump is finely crafted with a hygienic, stainless-steel frame, profiled elastomers, and mechanical seals. Utilizing a robust gearbox design, the pump is calibrated to operate quietly, efficiently, and at a reduced temperature to enhance safety.

There are also very few wear items on the pump. Alfa Laval’s Twin Screw has the ability to run for a very long time and requires very little maintenance.

When maintenance is needed, there are plenty of reasons to appreciate this pump. Alfa Laval’s diligent design provides true front-loading access to the pump’s seal and timing gears for easy servicing.

But what if a single piece of machinery could combine both rugged durability and smooth, agile productivity? As fate would have it, this type of versatility and precision actually exists, and it is embodied by the new Alfa Laval Twin Screw Pump.

TOP FEATURES AND FUNCTIONS:

What all can the versatile Twin Screw Pump do? Take a closer look at a few of its stand-out capabilities and learn why many food/beverage producers are buzzing about it.

THE FLEXIBILITY OF TWIN SCREW TECHNOLOGY

Although classified as a positive displacement pump, Alfa Laval’s Twin Screw can accomplish so much more. Unlike conventional positive displacement pumps which are primarily used for thick, viscous products, the new Twin Screw by Alfa Laval also has the ability to propel thin material like a centrifugal pump.

Gentle and virtually pulse-free, the Twin Screw is able to convey product through at various speeds for different viscosity liquids. This allows the pump to be utilized in a flexible manner within your production, adding significant value to producers with diverse ingredients, such as:

The Alfa Laval Twin Screw Pump is finely crafted with a hygienic, stainless-steel frame, profiled elastomers, and mechanical seals. Utilizing a robust gearbox design, the pump is calibrated to operate quietly, efficiently, and at a reduced temperature to enhance safety.

There are also very few wear items on the pump. Alfa Laval’s Twin Screw has the ability to run for a very long time and requires very little maintenance.

When maintenance is needed, there are plenty of reasons to appreciate this pump. Alfa Laval’s diligent design provides true front-loading access to the pump’s seal and timing gears for easy servicing.

TRIRO Three Screw Pump - E-Range

The E-range is designed for medium pressure high flow applications on clean liquids. It is constructed with a renewable sleeve and fabricated steel casing and features mechanical seal and optional integral relief valve as standard. Custom casing designs can be accommodated to meet client dimensions and specifications.To get more news about screw pump rotor, you can visit hw-screwpump.com official website.

API 676 AND OTHER SPECIFICATIONS

Triro E-range can be supplied in accordance with the requirements of API 676. Other international pump standards or clients specifications can be accomodated.

TURBOMECHANICAL SPECIFICATIONS

Triro E-range can be supplied to meet most turbomechanical specifications and applications including API 614 and API 610 (where relevant to P.D. Pumps).

NON STANDARD PUMPS

Triro E-range can be factory modified for special applications and higher viscosities.

* Bespoke and custom designs available

UNITIZATION

Pumps can be supplied bareshaft or assembled with the driver in various arrangements including vertical tanktop, pedestal and baseplate options, with spacer or non-spacer couplings and non spark guards.

TURBOMECHANICAL SPECIFICATIONS

Triro E-range can be supplied to meet most turbomechanical specifications and applications including API 614 and API 610 (where relevant to P.D. Pumps).

NON STANDARD PUMPS

Triro E-range can be factory modified for special applications and higher viscosities.

* Bespoke and custom designs available

UNITIZATION

Pumps can be supplied bareshaft or assembled with the driver in various arrangements including vertical tanktop, pedestal and baseplate options, with spacer or non-spacer couplings and non spark guards.

TURBOMECHANICAL SPECIFICATIONS

Triro E-range can be supplied to meet most turbomechanical specifications and applications including API 614 and API 610 (where relevant to P.D. Pumps).

NON STANDARD PUMPS

Triro E-range can be factory modified for special applications and higher viscosities.

* Bespoke and custom designs available

UNITIZATION

Pumps can be supplied bareshaft or assembled with the driver in various arrangements including vertical tanktop, pedestal and baseplate options, with spacer or non-spacer couplings and non spark guards.

TURBOMECHANICAL SPECIFICATIONS

Triro E-range can be supplied to meet most turbomechanical specifications and applications including API 614 and API 610 (where relevant to P.D. Pumps).

NON STANDARD PUMPS

Triro E-range can be factory modified for special applications and higher viscosities.

* Bespoke and custom designs available

UNITIZATION

Pumps can be supplied bareshaft or assembled with the driver in various arrangements including vertical tanktop, pedestal and baseplate options, with spacer or non-spacer couplings and non spark guards.

Chinese women it ‘doesn’t make sense’ to have babies

After three Lunar New Year holidays in a row disrupted by China’s zero-COVID policy, Ann Pei, Mona Zhao, and Wenyi Hai were thrilled to be able to leave Shanghai and return to their families for this year’s festive season.To get more news about woman in ancient china, you can visit shine news official website.

I knew that my mum and my grandparents would want to have a talk with me about marriage and children, especially since I’m in my thirties, and I wasn’t looking forward to that,” 31-year-old Ann Pei told Al Jazeera as she was preparing to head home to family near the city of Changchun in northeastern China.

Wenyi Hai, who is 24, knew that a similar conversation was waiting for her when she reached her family in Ji’an in central China.

“Normally, I can just excuse myself and hang up the phone when my parents start going on about husbands and babies, but when I am in their house, it’s not that easy to get away from the topic.”

Parents and older relatives are notorious for asking probing personal questions of young adults during Lunar New Year, especially of young women who are unmarried.Mona Zhao told her parents that she would only visit them in Qingdao in eastern China for the holidays if they agreed not to mention marriage and children.

“We have talked about that stuff a million times and I am sick of the discussion,” the 25-year-old explained.In January, China’s National Bureau of Statistics reported the population dropped by 850,000 people in 2022 – the first decline since the last year of the Great Famine in 1961.

The fall comes in the wake of a birth rate that has been steadily declining since the implementation of the one-child policy in 1980. It has continued to fall even though the policy was abolished in 2015, suggesting that 2022’s population drop was not an exception but the start of a trend. The issue is set to be one of the key areas of discussion at the annual meeting of China’s parliament, which begins at the weekend.

The problem for policymakers is that while women like Zhao, Pei and Hai are open to having a family one day, they are wary of marriage and motherhood because of the burdens and disadvantages it places on so many Chinese women.I don’t want my life to only be about taking care of kids, doing housework and taking care of my husband’s parents when they get old, but I feel like many families expect that from a married woman in China,” Hai said over a video connection.

Studies do indeed show that Chinese women carry the weight of most domestic tasks — spending about twice as much time on housework as their husbands, for instance.

“Also, it’s usually not enough with your husband’s salary in a family so you need to take care of a job on top of the duties at home,” Hai added, shaking her head in disbelief.

At the same time, the 24-year-old does not want a job that simply fits around the task of bringing up a child. She says she wants a career she can be proud of.

“I have a promotion coming up, and I would be risking it if I start making family plans now,” she explained.Even though it is illegal under Chinese law, some Chinese companies continue to make their female employees sign contracts that give the company the right to terminate them if they become pregnant.

In 2019, Fan Huiling from Guangdong Province was fired from her job when she notified her employer that she was pregnant. The same happened to a woman in Jilin Province the previous year.

Women able to reconcile pregnancy with their work life have discovered time off to have a baby can also come with great risks to their careers. Chinese women have reported being sidelined, demoted or replaced by their employers on returning to work from maternity leave.

Women do not even need to be pregnant to encounter discrimination. Sometimes simply being of childbearing age can be a problem, regardless of whether a woman is planning to start a family or not.

How Much Does it Cost to Install a Smart Door Lock in 2023?

The national average cost to install a smart door lock is $330, with most homeowners paying somewhere between $200 and $460. The lowest cost of this project is around $125 for simpler lock designs and easier installations, whereas complex, high-end models may take as much as $1,200 for installation and related services. To get more news about touch lock, you can visit securamsys.com official website.

Smart door locks are a perfect solution for a secure, keyless entrance. These devices are designed to operate with either a smartphone app, a PIN on a keypad, or a face or fingerprint scanner. They may also allow remote entry access and sync with home automation systems. In this cost guide, we’ll look at what it costs to install a smart door lock in 2023.

Average Costs to Install a Smart Door Lock

The cost to install a smart door lock varies depending on the type of door, smart lock model, and the complexity of installation. Here is the average cost of installing a smart door lock, including the labor and equipment.

On the low end of the spectrum, it costs just $125 to install a simple smart lock that attaches over an existing lock. And at the high end, you may pay as much as $1,200 to get a new smart lock with biometric technology installed by an expert. On average, the common Wi-Fi-enabled smart lock installation costs $330 if you call a handyman or locksmith.

Smart Door Lock Installation Cost by Lock Type

There are many kinds of smart locks, each with its own features and functionality. Some might require a steady internet or Bluetooth connection while others might need specific accessories to work.

Let’s take a look at different types of smart locks and their costs, excluding the labor cost of installing them:

Wi-Fi-Enabled Smart Lock

As the name implies, Wi-Fi smart locks work off a Wi-Fi connection and allow you to access and check your home security remotely. You can change codes, lock and unlock doors, or check if there’s a breach.

Wi-Fi-enabled smart door locks are compatible with all kinds of home systems, be it Amazon Alexa, Google Home, or Apple Siri, and operate with a phone app. Most designs do not need an adapter or additional hub to work. Excluding the installation costs, a Wi-Fi smart lock typically costs $200 to $300 per lock where cost varies with features, brand, etc.

Bluetooth Smart Door Lock

Bluetooth smart door lock systems come with almost the same features as a Wi-Fi-enabled smart lock. You can unlock and lock doors, set new codes, set auto locks, and unlock them remotely.

A basic Bluetooth smart lock unit costs around $170 to $260 and works with a mobile app. The only drawback of these smart locks is that they have a limited range of 40 to 50 feet.

RFID Smart Door Lock

Radio Frequency Identification, or RFID, wireless systems consist of two components: readers and tags. An RFID smart lock uses a keycard, just like locks in hotel rooms or offices. The system uses electromagnetic waves to transmit signals between the card and the lock. Contactless debit or credit card payments work on the same principle. So, no need to worry about forgetting your keys.

Some RFID lock models are completely contactless, while others require a physical connection between the lock pad and the card. You have the freedom to choose between a microchip card or a key fob-style access card according to your home security system and convenience.

Biometric Smart Door Lock

Biometric lock systems employ a combination of PINs and fingerprints to lock and unlock doors. They use a touchscreen design featuring biometric technology that scans and recognizes your fingerprint to unlock the door.

RFID, keypad, and smartphone app access are often integrated into these locks as backup methods. Many biometric lock models also work with smart home automation systems. Depending on the features and model you pick, biometric units generally cost $200 – $350.

Z-Wave Smart Door Lock

These smart locks use Z-Wave radio frequency technology to integrate with your smart home control system. You can program and control the lock with a smartphone app. Some models come with advanced features such as enhanced security inputs and automatic door locking, but they mostly need a hub or Alexa device to work. On average, locks with Z-wave capability cost $240 to $360.

Smart Door Lock Installation Cost by Lock Type

There are many kinds of smart locks, each with its own features and functionality. Some might require a steady internet or Bluetooth connection while others might need specific accessories to work.

Let’s take a look at different types of smart locks and their costs, excluding the labor cost of installing them:

Wi-Fi-Enabled Smart Lock

As the name implies, Wi-Fi smart locks work off a Wi-Fi connection and allow you to access and check your home security remotely. You can change codes, lock and unlock doors, or check if there’s a breach.

Wi-Fi-enabled smart door locks are compatible with all kinds of home systems, be it Amazon Alexa, Google Home, or Apple Siri, and operate with a phone app. Most designs do not need an adapter or additional hub to work. Excluding the installation costs, a Wi-Fi smart lock typically costs $200 to $300 per lock where cost varies with features, brand, etc.

Bluetooth Smart Door Lock

Bluetooth smart door lock systems come with almost the same features as a Wi-Fi-enabled smart lock. You can unlock and lock doors, set new codes, set auto locks, and unlock them remotely.

A basic Bluetooth smart lock unit costs around $170 to $260 and works with a mobile app. The only drawback of these smart locks is that they have a limited range of 40 to 50 feet.

RFID Smart Door Lock

Radio Frequency Identification, or RFID, wireless systems consist of two components: readers and tags. An RFID smart lock uses a keycard, just like locks in hotel rooms or offices. The system uses electromagnetic waves to transmit signals between the card and the lock. Contactless debit or credit card payments work on the same principle. So, no need to worry about forgetting your keys.

Some RFID lock models are completely contactless, while others require a physical connection between the lock pad and the card. You have the freedom to choose between a microchip card or a key fob-style access card according to your home security system and convenience.

Biometric Smart Door Lock

Biometric lock systems employ a combination of PINs and fingerprints to lock and unlock doors. They use a touchscreen design featuring biometric technology that scans and recognizes your fingerprint to unlock the door.

RFID, keypad, and smartphone app access are often integrated into these locks as backup methods. Many biometric lock models also work with smart home automation systems. Depending on the features and model you pick, biometric units generally cost $200 – $350.

Z-Wave Smart Door Lock

These smart locks use Z-Wave radio frequency technology to integrate with your smart home control system. You can program and control the lock with a smartphone app. Some models come with advanced features such as enhanced security inputs and automatic door locking, but they mostly need a hub or Alexa device to work. On average, locks with Z-wave capability cost $240 to $360.

Smart Door Lock Installation Cost by Lock Type

There are many kinds of smart locks, each with its own features and functionality. Some might require a steady internet or Bluetooth connection while others might need specific accessories to work.

Let’s take a look at different types of smart locks and their costs, excluding the labor cost of installing them:

Wi-Fi-Enabled Smart Lock

As the name implies, Wi-Fi smart locks work off a Wi-Fi connection and allow you to access and check your home security remotely. You can change codes, lock and unlock doors, or check if there’s a breach.

Wi-Fi-enabled smart door locks are compatible with all kinds of home systems, be it Amazon Alexa, Google Home, or Apple Siri, and operate with a phone app. Most designs do not need an adapter or additional hub to work. Excluding the installation costs, a Wi-Fi smart lock typically costs $200 to $300 per lock where cost varies with features, brand, etc.

Bluetooth Smart Door Lock

Bluetooth smart door lock systems come with almost the same features as a Wi-Fi-enabled smart lock. You can unlock and lock doors, set new codes, set auto locks, and unlock them remotely.

A basic Bluetooth smart lock unit costs around $170 to $260 and works with a mobile app. The only drawback of these smart locks is that they have a limited range of 40 to 50 feet.

RFID Smart Door Lock

Radio Frequency Identification, or RFID, wireless systems consist of two components: readers and tags. An RFID smart lock uses a keycard, just like locks in hotel rooms or offices. The system uses electromagnetic waves to transmit signals between the card and the lock. Contactless debit or credit card payments work on the same principle. So, no need to worry about forgetting your keys.

Some RFID lock models are completely contactless, while others require a physical connection between the lock pad and the card. You have the freedom to choose between a microchip card or a key fob-style access card according to your home security system and convenience.

Biometric Smart Door Lock

Biometric lock systems employ a combination of PINs and fingerprints to lock and unlock doors. They use a touchscreen design featuring biometric technology that scans and recognizes your fingerprint to unlock the door.

RFID, keypad, and smartphone app access are often integrated into these locks as backup methods. Many biometric lock models also work with smart home automation systems. Depending on the features and model you pick, biometric units generally cost $200 – $350.

Z-Wave Smart Door Lock