freeamfva's blog

Installing Large Format Thin Porcelain Panels

Have you seen the wave of new “thin porcelain bodied panels” that have hit the market? These product types range in thickness from ~1/8” (3.5mm) to 5/16” (7mm) and some may be manufactured with a resin or mesh backing. Undoubtedly, the resin or mesh backing provides stability to the thin porcelain panels. Many of the manufacturers of these slim porcelain panel products are suggesting that their products can be used for interior vertical applications and limited interior floor applications. Consult with the thin porcelain panel manufacturer for their recommendation on which specific panel type and thickness is suitable for a specific application. Note that not all thicknesses in a manufacturer’s product range are suitable for all applications. Exterior applications and demanding floor applications may require the use of a specific manufacturer’s porcelain panel (type and thickness) that has been rated for the application and area of use.Get more news about Thin Porcelain Tile,you can vist our website!

LATICRETE International, Inc., the world leader in ceramic tile and stone installation systems, has had a long and successful history of installing thin, ceramic tile panels dating back to the early 1970’s. Based on our successful track record, the following installation systems can be specified for today’s innovative, thin porcelain panel installation challenges. Special installation techniques are required for successfully installing thin-body porcelain panels. For example, using a glass installer’s “vacuum suction cups” and / or “installation frames” can facilitate easier handling and placing of the panels and reduce the chance of cracking them during handling and installation. Consult the thin porcelain panel manufacturer before selection and installation to determine the porcelain panel’s suitability for the intended area of use and the specified project. It is highly recommended that the manufacturer of the thin porcelain tile provide information regarding the tile’s suitability and acceptability for the intended use of the tile and for the service rating of the tile.

SUBSTRATE PREPARATION:

The main challenge for installers is to make sure that the substrate is extremely flat, so as to achieve the required coverage. Floor installations of thin-body porcelain panels are only recommended over interior concrete floor slabs (and approved existing interior ceramic tile over concrete) that meet the maximum allowable deflection standard of L/360 under total anticipated load. Installations over wood-framed floor constructs are not suitable for most of these panels. Floor substrates for the installation of thin-body porcelain veneer panels must be prepared to a Floor Flatness (FF) of 50. The floor flatness (FF) requirements should be determined just prior to the installation of the thin porcelain tile/panels. If the slab does not meet the floor flatness requirements then appropriate surface preparation should be conducted. Maximum variation in the substrate is not to exceed 1/8” in 10’ (3mm in 3m) from the required plane, and no more than 1/16” in 12” (1.5mm in 30cm) when measured from high points. Please refer to LATICRETE TDS 233 “Floor Flatness (FF) and Floor Levelness (FL)” for more information. Typical interior wall substrates are concrete, concrete block and cement backer board. Typically, the following LATICRETE Polymer Fortified Mortars and LATICRETE® or DRYTEK® Self-Leveling Underlayments can be used to properly prepare a substrate prior to the installation of these thin porcelain panels:

In some cases, requests have been made to use thin profile porcelain panels on exterior applications. Please note that for exterior veneer installations, the thickness of the panels can be a concern. The 2012 International Building Code (IBC) - Chapter 14 – Exterior Walls - requires that “adhered veneer finish types” (which include ceramic and porcelain tiles) be a minimum of ¼” (6mm) thickness for use as exterior cladding. In addition, facial size dimensions can also be a factor. For porcelain tile, the 2012 IBC [Section 1405.10.2] requires that exterior adhered porcelain tile be a maximum of 24” (610mm) in any face dimension nor more than 3 square feet (0.28m2) in total face area and shall not weigh more than 9 lbs. per s.f. (44.2 kg/m2).

The Best Meat Tenderizers for the Juiciest Steaks

We independently research, test, review, and recommend the best products—learn more about our process. If you buy something through our links, we may earn a commission.Get more news about Cuber Perforator Machine,you can vist our website!

The meat tenderizer is the hero of the budget cook. These simple tools, and a little elbow grease, take a tough cut of chuck or chicken and transform it into a softer-to-chew, flavorful protein by physically breaking down dense tissue and fibers.

There are a couple considerations to make when shopping for a meat tenderizer that will properly turn tough cuts into ready-to-cook meats that taste as tender as more expensive varieties. Look for a model that sits comfortably in your grip and is not too heavy to avoid hand fatigue. Also, keep in mind the types of tasks you will perform. If you prefer creating cuts in the meat to help marinades and seasonings get in deep, go for the bladed or needled models. If you are a fan of schnitzel and piccata preparations, be sure to get one of the mallet-style tenderizers. If you want something easy, you should also consider a dishwasher-safe version.

From models with retractable blades and safety locks to traditional double-faced mallets, these are the best meat tenderizers.Who else recommends it? Bob Vila also picked the Oxo Good Grips Bladed Meat Tenderizer.1

What do buyers say? 76% of 800+ Amazon reviewers rated this product 4 stars or above.

Take your steak from tough and chewy to tender and juicy with the help of a tenderizer, such as this bladed version from Oxo. It has 50 sharp blades that slice through the meat's tough fibers to create channels for marinades to penetrate easily. The rounded top fits comfortably in the palm, so it’s easy to tackle enough steaks for a whole dinner party. A clear base makes it easy to control the placement of the blades for even tenderizing. When it’s time to store the tenderizer, a toggle lock keeps the blades covered, and because the lock is recessed, it won’t unlock accidentally. It’s dishwasher safe and comes apart for more thorough cleaning.Get the job done with this budget tenderizer made from plastic and no moving parts. Rather than thin blades, it has spikes that leave larger holes to hold marinades and spices. Since the spikes aren’t as hard or sharp as metal blades, this tenderizer can be left loose in the kitchen gadget drawer without worrying about accidental cuts. The top handle is comfortable to hold when pressing the tenderizer into the meat, and it’s safe enough for kids to use. When it’s not being used for steaks, this tenderizer can be used to poke holes in potatoes or dock dough before baking. It should be washed by hand.

Mallet-style meat tenderizers are quite popular and easy to use. This one can be wielded one-handed or with one hand over the other for a bit more power or control. There's a smooth side for flattening meat without creating any holes and a side with pyramid-shaped teeth for tenderizing. The head is angled so it hits the meat flatly while using a normal hammering motion. Like other Oxo products, this tenderizer has a comfortable, soft-touch handle.

How is CNC Swiss machining different from CNC turning?

CNC Swiss lathes differs from traditional lathes and turning centers because of the way that the tool meets the stock. In a CNC turning center, tools are arranged on round turret with tooling slots. The bar stock is fed through a bar feeder and the turret is programmed to rotate and articulate on the X, Y & Z-axis to meet the bar stock to cut the material. Certain CNC turning centers have more than one spindle.Get more news about Precision Swiss Lathe,you can vist our website!

In a dual spindle CNC turning center, the part is fed from the originated spindle to the secondary spindle where the other side of the part can have additional machining performed. The turrets on dual-spindle CNC turning centers have tool slots on both sides of the turret and can make more complex parts than those with a single spindle. The bar sizes that can be fed into a CNC turning center can be a lot larger than for Swiss CNC lathes. Bar feeders on CNC turning centers feed the bar but do not articulate it to the tool. The tool (on the turret) is programmed to move to the bar.

Swiss Lathes Make Smaller Parts from Bar Stock

CNC Swiss lathes typically make parts under 2 in outer diameter. They operate by moving a fixed tooling jig to the bar stock. These tools cut very close to the spindle makes tool changes very quick. The key difference between CNC Swiss and CNC turning centers is how the bar feeder and spindle work together to produce parts. The spindle on a Swiss CNC lathe controls the bar movement against a stationary tool on the tooling jig.

The bar does the moving instead of the tool. All of the cutting is done right next to the collet. This differs from a CNC turning center where the cutting occurs as the tool moves to the bar.

CNC Swiss Lathes are Great for Long Parts

If you are making a cylindrical part that is OD by 6 long with some features like threads and slots, it could be made on either a CNC turning center or a Swiss lathe. However, on the CNC turning center, the tool would move along the length of the part which can introduce some slop in the cutting towards the end of the part. But in a CNC Swiss lathe, the cutting would always be near the collet, so the part would stay round and within the same tolerance range at the front of the part as the end of the part. This makes Swiss lathes great for any parts that need to be precise (+/-.001 is feasible) and long as compared to the outer diameter.

CNC Swiss Lathes are Great for Production Quantities

Swiss Lathes are great for high production work. When combined with a bar feeder, they are designed to run lights-out and produce parts unattended. With proper programming and operator input, they can make precise parts to specification with a high level of repeatability, often with cycle times under a minute. Many Swiss have a sub-spindle that allows live tooling work to be done on the back side of one part simultaneous to the front size of another part essentially cutting in half the cycle time.

Molekularsieb 4A

4A Molekularsieb Typ 4A Molekularsieb ist ein alkalisches Aluminiumsilikat; es ist eine Natriumform der kristallinen Struktur des Typs A. Das molekulare Sieb 4A hat eine effektive porenöffnung von etwa 4 Angström (0,4 Nm). Ein Molekularsieb vom Typ 4A adsorbiert die meisten Moleküle mit einem kinetischen Durchmesser von weniger als 4 Angström und schließt diejenigen aus, die größer sind. Solche adsorbierten Moleküle umfassen einfache Gasmoleküle wie Sauerstoff, Stickstoff, Kohlendioxid und direktkettige Kohlenwasserstoffe.Get more news about Molekularsieb 4a,you can vist our website!

Verzweigtkettige Kohlenwasserstoffe und aromatische Substanzen sind ausgeschlossen. Eine typische Anwendung ist: a) trocknen und entfernen von CO2 aus Erdgas, Flüssiggas, Luft, inerten und atmosphärischen Gasen usw b) Entfernung von Kohlenwasserstoffen, Ammoniak und Methanol aus Gasströmen (Ammoniak-sing-Gasreinigung) c) spezielle Typen werden in luftfrachtanlagen von Bussen, Lastwagen und Lokomotiven verwendet. d) verpackt in kleinen Taschen, kann es einfach als verpackungsentfeuchter verwendet werden. 4A Molekularsieb Regeneration Ein Molekularsieb vom Typ 4A kann entweder durch erhitzen bei Prozessen mit wärmeschwankungen oder durch Druckabfall bei Druckabfall regeneriert werden.

Um Feuchtigkeit aus dem molekularen Sieb 3A zu entfernen, ist eine Temperatur von 200-230°C erforderlich. Ein richtig regeneriertes Molekularsieb kann eine Taupunkt-Temperatur für Feuchtigkeit unter -100 ° C erzeugen. Die Konzentration am Ausgang während des differenzdruckprozesses hängt vom vorhandenen Gas und von den Prozessbedingungen ab. Achtung! Um das eindringen von Kohlendioxid oder die voradsorption von organischen Stoffen zu vermeiden, muss es vor dem Start erneut aktiviert werden. Geliefert in einem Behälter: Stahlfass -150 kg. Die Kosten für die Verpackung - 100 $ pro Tonne. Karton Fass - 30 kg. Die Kosten für die Verpackung - 60 $ pro Tonne. Karton-25 kg. Die Kosten für die Verpackung - 40 $ pro Tonne.

What is CNC Machining?

CNC 101: The term CNC stands for 'computer numerical control', and the CNC machining definition is that it is a subtractive manufacturing process that typically employs computerized controls and machine tools to remove layers of material from a stock piece—known as the blank or workpiece—and produces a custom-designed part. This process is suitable for a wide range of materials, including metals, plastics, wood, glass, foam, and composites, and finds application in a variety of industries, such as large CNC machining, machining of parts and prototypes for telecommunications, and CNC machining aerospace parts, which require tighter tolerances than other industries. Note there is a difference between the CNC machining definition and the CNC machine definition—one is a process and the other is a machine. A CNC machine (sometimes incorrectly referred to as a C and C machine) is a programmable machine that is capable of autonomously performing the operations of CNC machining.Get more news about Desktop Cnc Machine Parts,you can vist our website!

CNC machining as a manufacturing process and service is available worldwide. You can readily find CNC machining services in Europe, as well as in Asia, North America, and elsewhere around the globe.

Subtractive manufacturing processes, such as CNC machining, are often presented in contrast to additive manufacturing processes, such as 3D printing, or formative manufacturing processes, such as liquid injection molding. While subtractive processes remove layers of material from the workpiece to produce custom shapes and designs, additive processes assemble layers of material to produce the desired form and formative processes deform and displace stock material into the desired shape. The automated nature of CNC machining enables the production of high precision and high accuracy, simple parts and cost-effectiveness when fulfilling one-off and medium-volume production runs. However, while CNC machining demonstrates certain advantages over other manufacturing processes, the degree of complexity and intricacy attainable for part design and the cost-effectiveness of producing complex parts is limited.

While each type of manufacturing process has its advantages and disadvantages, this article focuses on the CNC machining process, outlining the basics of the process, and the various components and tooling of the CNC machine. Additionally, this article explores various mechanical CNC machining operations and presents alternatives to the CNC machining process.

Are you between jobs right now or an employer looking to hire? We've got you covered with our in-depth collections of resources for industrial job seekers and employers looking to fill roles. If you have an open position, you can also fill out our form for a chance to have it featured in the Thomas Monthly Update newsletter.

Evolving from the numerical control (NC) machining process which utilized punched tape cards, CNC machining is a manufacturing process which utilizes computerized controls to operate and manipulate machine and cutting tools to shape stock material—e.g., metal, plastic, wood, foam, composite, etc.—into custom parts and designs. While the CNC machining process offers various capabilities and operations, the fundamental principles of the process remain largely the same throughout all of them. The basic CNC machining process includes the following stages:

The CNC machining process begins with the creation of a 2D vector or 3D solid part CAD design either in-house or by a CAD/CAM design service company. Computer-aided design (CAD) software allows designers and manufacturers to produce a model or rendering of their parts and products along with the necessary technical specifications, such as dimensions and geometries, for producing the part or product.

Designs for CNC machined parts are restricted by the capabilities (or inabilities) of the CNC machine and tooling. For example, most CNC machine tooling is cylindrical therefore the part geometries possible via the CNC machining process are limited as the tooling creates curved corner sections. Additionally, the properties of the material being machined, tooling design, and workholding capabilities of the machine further restrict the design possibilities, such as the minimum part thicknesses, maximum part size, and inclusion and complexity of internal cavities and features.

Is commercial plywood termite resistant?

Will termites destroy plywood floors or furniture? Short answer - yes! If you have a history of termite infestation at home and even locally, it makes sense to take steps to prevent future infestation. For example, if you want to build new furniture with plywood, it is logical to choose the anti-white ant plywood.To get more news about commercial plywood, you can visit boosterplywood.com official website.

In general, plywood can obtain proper structure by gluing all kinds of plywood together. These sheets are basically made from logs from different tree species. For this reason, you will find a variety of veneer plywood, because the wood used depends entirely on the geographical location of its manufacture. For example, rubber plywood is mainly imported from southern India.

It is important to note that although different plywood uses different kinds of wood from different species, it shows the same basic characteristics. In fact, the interior material remains the same, with the only difference being the treatment used on it and the adhesive used to bond the panels together.

2.How to avoid furniture being eroded by termites

However, before doing all the operations, here are some instructions to prevent your furniture from being turned into sawdust by termites.

1.buy termite resistant plywood: chemically treated plywood can usually be moisture resistant and fire resistant. The strong combination between the wood layers ensures high durability and resistance to destruction. In our catalogue, you will encounter products such as green defensers, plywood that can resist termites.

2. prevent contact with outdoor ground: this is almost the most major sin if wooden furniture is placed on a garden or lawn. Ensure that furniture is not in contact with soft soil. Place your table, bench and chair on cement or tile surfaces. If the column must be placed on the ground to hang the clothesline or to set the canopy, make sure to build a sealed concrete foundation around each column.

3. laminated wood: indeed, termites can eat laminated or chemically treated wood, but they seem to be only the last option. Make sure the wood is coated with many laminates.

3.What is the difference between wooden plywood, commercial plywood, and hardwood plywood

Wooden plywood is redundant as all plywood has been made of wood. commercial plywood usually refers to grade plywood, most often refers to grade MR plywood (IS 303), it is basically the cheapest plywood in the market. So in india market you will find someone asking to use commercial plywood or commercial grade plywood, which usually means they want cheap MR (moisture proof/ IS 303) grade plywood. These plywood are usually made from a combination of cork and hardwood wood or only cork wood. Hardwood plywood usually refers to the manufacture of plywood, which is used to construct plywood layers of wood. Hardwood is usually attributed to hardwood wood species such as eucalyptus, Guerran, and birch, which are more dense and have longer service life than other wood species such as rubber or poplar. Plywood made of hardwood wood is usually heavier in weight, more dense and longer in life than hardwood plywood. i recommend choosing hardwood plywood made from eucalyptus wood to ensure that the plywood is strong, durable and, most importantly, from ecologically sustainable cultivation.

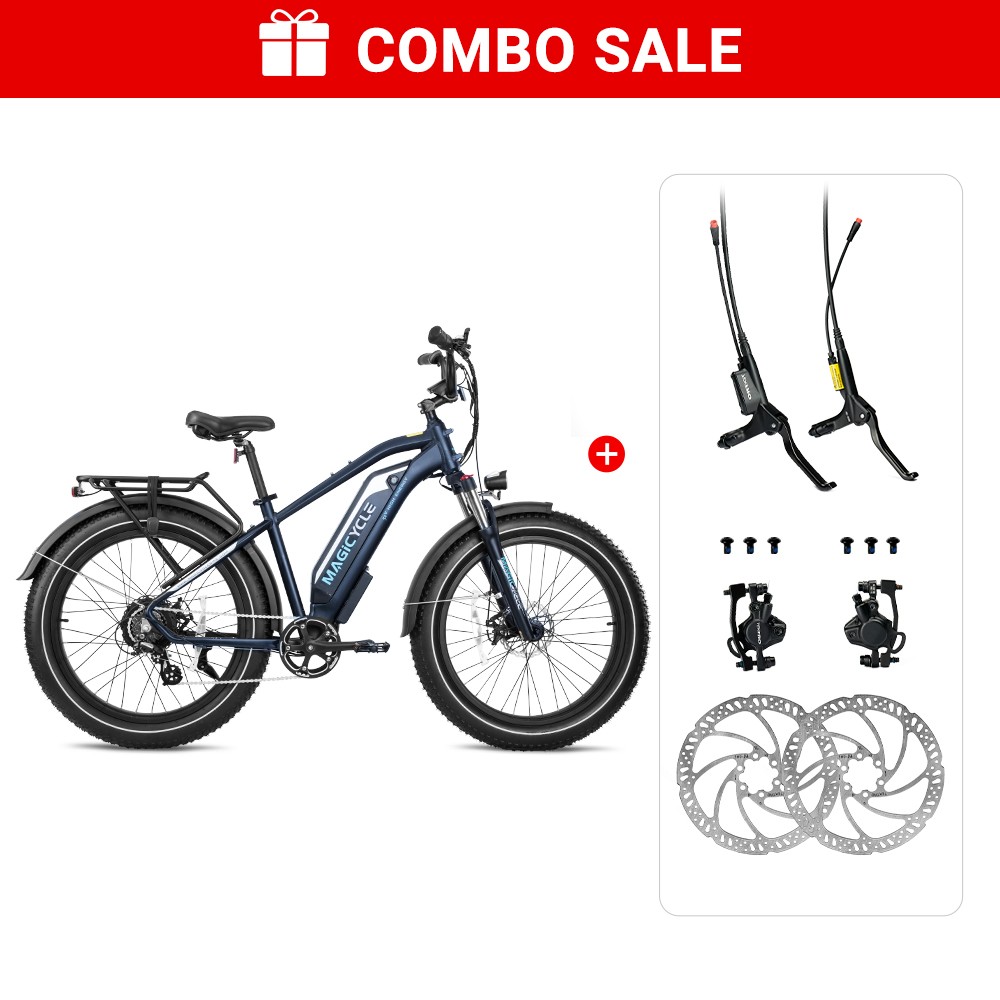

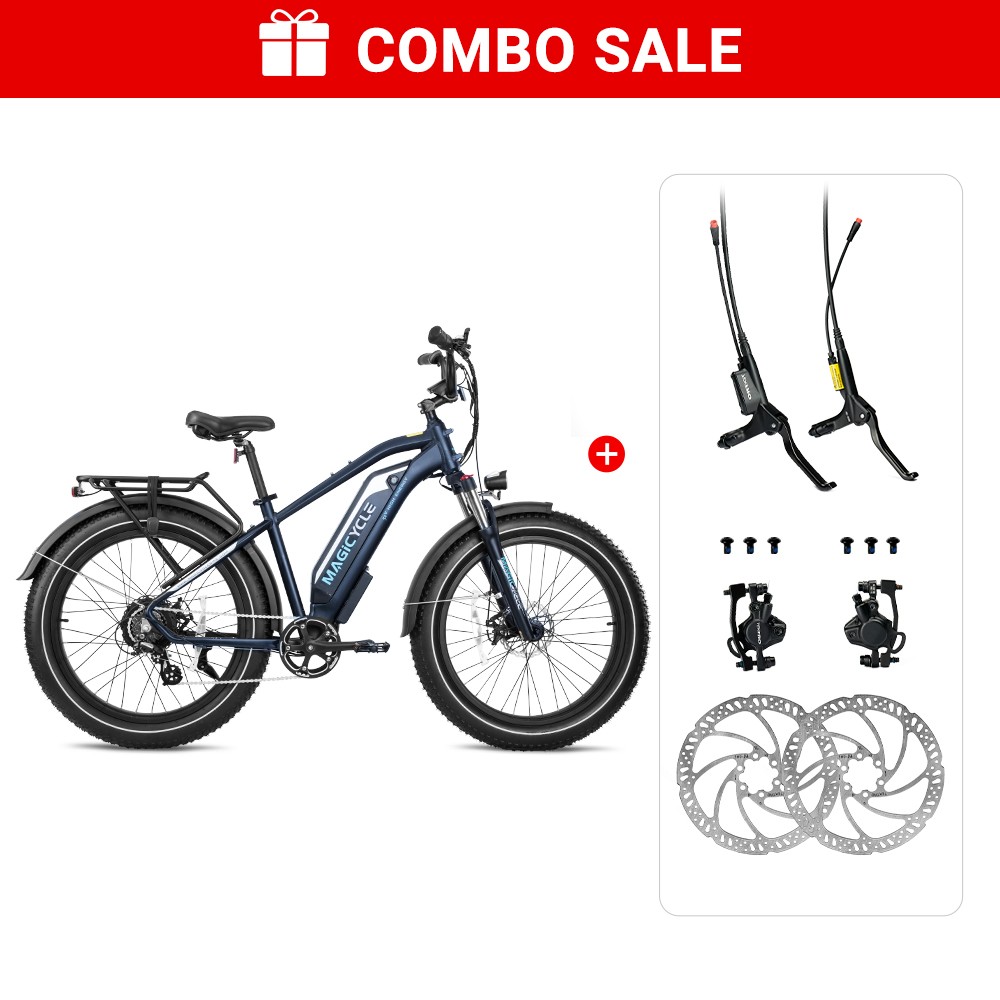

CAN A FAT E-BIKE BE YOUR ONLY BIKE?

Are you interested in biking, but hesitant to buy a traditional bike because of the cost or the fear of cycling in heavy traffic? If so, you may want to consider purchasing an electric bike, or "e-bike." E-bikes are becoming increasingly popular as a convenient and affordable transportation option. In this blog post, we will explore some of the pros and cons of owning an e-bike as your only form of transportation.To get more news about fatest ebike, you can visit magicyclebike.com official website.

Fat tire e-bikes are a type of electric bicycle that is designed for off-road riding. The tires are much wider than those on a standard bicycle, and they provide ample stability and traction on rough terrain. The motor on a fat tire e-bike provides power assistance to the rider, making it easier to pedal up hills or against strong headwinds. Fat tire e-bikes are an ideal choice for riders who enjoy spending time in nature, and they can even be used for commuting in areas with poor road conditions. To get more news about 52V Ebike, you can visit magicyclebike.com official website.

So, can a fat e-bike be your only bike? In many ways, yes. Fat bikes are versatile machines that can handle a wide variety of terrain and conditions. They're also relatively affordable, which makes them a great option for people who want to get into cycling without breaking the bank. And, of course, the biggest advantage of fat bikes is that they're electric-powered, which means you'll never have to pedal up a hill again! However, there are a few things to keep in mind before you make the switch to an e-fat bike. First, while fat bikes are designed to be ridden on all types of terrain, they may not be as efficient on paved roads as traditional road bikes. Second, fat bikes can be heavier and more difficult to transport than other types of bicycles. And finally, while electric-assist fat bikes can make pedaling easier, they won't do all the work for you – you'll still need some muscle power to get up those hills!To get more news about himiway ebike, you can visit magicyclebike.com official website.

1- RIDE THE UNEXPLORED GROUNDS

A fat tire bike is an excellent choice for those looking to explore new ground. These bikes are built for stability and comfort, with wide tires that provide ample traction. Fat tire bikes are also highly versatile, able to tackle a variety of terrain. Whether you're riding on sand, snow, or mud, a fat tire bike will help you keep your footing. Additionally, fat tire bikes are typically outfitted with a suspension system that helps to absorb bumps and shocks. This makes for a smoother ride, even over rough terrain. So if you're looking to venture off the beaten path, a fat tire bike is a perfect choice.

2- PRACTICAL VERSATILITY

Another reason to consider a fat tire bike as your only bike is the practical versatility that these bikes offer. Fat tire bikes are just as comfortable on city streets as they are on off-road trails. And, because of their wide tires, they're able to navigate a variety of terrain and obstacles. Additionally, many fat-tire bikes come equipped with features that make them more versatile than traditional bikes. For example, some fat-tire bikes have racks or baskets that allow you to carry cargo. Others come equipped with lights and reflectors, making them safer to ride in low-light conditions. And, some fat tire bikes even have electric motors that assist with pedaling, making them a great choice for commuters.

3- KEEPING IT SIMPLE

For some, the appeal of a fat tire bike is that it's a simple machine. These bikes don't have all the bells and whistles of other bikes on the market. They're typically outfitted with just the basics – wide tires, a comfortable seat, and simple components. This makes for a bike that's easy to maintain and repair. Additionally, fat tire bikes are often less expensive than other types of bikes. So if you're looking for a bike that's low-maintenance and budget-friendly, a fat tire bike is a great choice.

4- KEEP PUNCTURES AT BAY

One of the benefits of riding a fat tire bike is that you're less likely to experience flats. That's because the wide tires on these bikes provide more surface area, which helps to distribute your weight more evenly. This decreases the likelihood of punctures, as there is less pressure on any one spot. Additionally, the wide tires on fat-tire bikes provide more traction, which can help to prevent flats caused by skidding or sliding. So if you're looking for a bike that can help you avoid flats, a fat tire bike is a great choice.

5- KEEP FIT ON THE FAT BIKE

Riding a fat tire bike is a great way to stay fit. These bikes provide a low-impact workout that's easy on the joints. And, because fat-tire bikes are so versatile, you can use them for a variety of activities. For example, you can use them for leisurely rides around the neighborhood or for more intense workouts on off-road trails. Additionally, many people use fat tire bikes for commuting, as they provide a great way to get some exercise while getting to and from work. So if you're looking for a bike that can help you stay fit, a fat tire bike is a great choice.

6- IDEAL FOR BIKE PACKING

Another reason to consider a fat tire bike as your only bike is that they're ideal for bike packing. Bike packing is a type of cycling that involves riding long distances with all of your gear packed onto your bike. And, because fat-tire bikes are so versatile, they make an ideal choice for this activity. Fat tire bikes are able to tackle a variety of terrain, making them great for exploring off-road trails. Additionally, many fat-tire bikes come equipped with features that make them more suitable for bike packing, such as racks or baskets for carrying gear. So if you're looking to get into bikepacking, a fat tire bike is a great choice.

7- GET BETTER DOWNHILL TRACTION

If you enjoy riding off-road, you know that traction is key. And, while all bikes provide some traction, fat-tire bikes offer more traction than other bikes. That's because the wide tires on these bikes provide more contact with the ground. This gives you more control when riding on loose or slippery surfaces. Additionally, the wide tires on fat-tire bikes can help you float over sand and snow, making them a great choice for riding in beach or winter conditions. So if you're looking for a bike that provides better traction, a fat tire bike is a great choice.

8- FUN TO RIDE

In addition to all of the practical reasons to ride a fat tire bike, they're also just plain fun to ride. These bikes are stable and comfortable, making them great for leisurely rides. And, because they can tackle a variety of terrain, they're also great for exploring new riding areas. Additionally, many people find that the wide tires on fat-tire bikes make for a smoother ride. So if you're looking for a bike that's fun to ride, a fat tire bike is a great choice.

Super 73-Z Miami review: An e-bike that conquers any commute

Speaking of smells, commuting, as a general rule, stinks. It’s purgatory. It’s the thing you do before the thing you’re trying to do. At its best, it’s waiting. At its worst, it’s a biblical level of transit-based suffering. Like many kinds of pain in this world, however, technology has a salve — in this case, an old solution, turned new. I’m talking about electric bikes, or more specifically, Super73’s electric bikes.To get more news about fatest ebike, you can visit magicyclebike.com official website.

Super73 has made a name for itself in a crowded electric mobility space, collecting accolades from the likes of Casey Neistat and finding its e-bikes under the butts of celebrities like Justin Bieber. Its iconic low-set, retro-futuristic frame, and luxurious bench-style seat make its two-wheelers instantly recognizable. But looks —while endlessly valuable for attracting customers — do little to quell the sticker shock of most newcomers looking to invest in a brand new e-bike.To get more news about 52V Ebike, you can visit magicyclebike.com official website.

Riding down 5th Avenue on Super73’s-Z Miami, I feel two things: fear for my life, given the fact I’m riding an e-bike in bumper-to-bumper traffic, but primarily, I feel pure, unadulterated elation. In this particular traffic clusterfuck, I’m beating the system.To get more news about himiway ebike, you can visit magicyclebike.com official website.

The Super73-Z Miami is the company’s new addition to its Z-series lineup. One of the biggest changes here is the e-bike’s light frame, which is made from aluminum. The frame obviously makes the e-bike easier to manipulate while you’re not riding, but it also makes the riding experience feel airy and agile. Which — back to my jaunt down 5th Avenue — is important if you’re weaving in and out of tempestuous NYC traffic. The whole e-bike weighs about 59 pounds, which for an e-bike of the Miami’s specifications, isn’t bad. I carried it up a few subway steps as a test, just to prove that it is doable if you don’t mind breaking a little sweat.

Just like how the Terminator’s T-800 is built to destroy, Super73’s Miami is purpose-made to mow down most concrete commutes. “Retro Urban Tires” measure four inches wide and come with compact treads, while a smart display integrated with Super73’s app can give you turn-by-turn navigation.

While I didn’t get a chance to test the Miami’s smart display (an unregistered review e-bike prevented me from using the app), I can say with certainty that the tires passed the urban commuting exam with flying colors.

Even with a foe as formidable as New York City’s decrepit infrastructure, the Miami was able to get me up and down Manhattan with ease. Thick tires helped me cruise over rocks and crags, and even glide safely over speed bumps. When I needed to cross the threshold from street to sidewalk, the Miami chewed up the curb like it was made by Gerber.High top speed/acceleration usually connotes danger, but I’ve come to learn (in my e-mobility pursuits) that commuting environments, where riders are thrust into sandwich-like situations with cars, trucks, and disgruntled cabbies, require the ability to speed up and stay moving on a dime.

I can assure you that the Miami has what you need to keep going. I zipped in and out of traffic, around slow movers in the bike lane, and careened around careless pedestrians. For those times when you need to slow down, the Miami also has various speed settings. You can even cosplay as a regular bicyclist with four levels of pedal assist, though frankly, I’ll always be a thumb throttle kind of person. Who am I trying to fool, anyway?I should note that the Miami’s highest speed setting is called “off-road” mode, suggesting that one shouldn’t have it activated while zooming around town. Between you and me (and everyone else reading this review), I had the highest speed setting (up to 28 mph) engaged at some point during all of my test trips. Just because I can go over the 25 mph e-bike speed limit doesn’t mean I will. (Narrator: He definitely went over the speed limit.)

Shapr3D releases new 2D drawing feature and pricing tiers

The rapid pace of development of Shapr3D, CAD modeler for iPad and macOS, has been a point of attention. It caused a stir after being optimized for the new Macs with the M1 processor. Shapr3D founder István Csanády says CAD software should be easier to learn and use. Keeping the focus on end user is important. While celebrating 5 years of its journey to developing CAD program, Shapr3D recently introduced 2D drawing feature. Now a user can draft 2D drawings of 3D models in the Shapr3D app. These drawings are diagrams that show how a part, component, or any object functions and how that object is constructed or structured. Through these drawings, designers can effectively communicate their ideas and decisions. The manufacturers can visualize and tweak the designs. The feature enhances collaboration on the production floor.

The 2D drawings feature is available only for Shapr3D Business plan users. The existing active Pro users will be upgraded at no extra cost to the business package for $499 per year or $59 per month. Business users will be able to create 2D views from a 3D body and save them as DWG or DXF files. The plan also includes unlimited CAD imports/exports, designs, and workspaces, as well as seamless integration with the desktop CAD.To get more news about 2d drafting, you can visit shine news official website.

Shapr3D has also introduced its new Hobby package, priced at $149 per year or $30 per month, which comes with STL export for 3D printing, 10 workspaces, export for Apple AR. It is available for personal use. However, Shapr3D’s educational license is free for students, teachers and faculty members of accredited educational institutions.

Logistics robots: the rise of automation in warehousing

Logistics robots are a growing trend that has really taken off in recent years. The progressive complexity of warehousing and the demand for agile and efficient operations have caused companies to invest in automating movements as well as the different areas in the facility with automated storage and retrieval systems (AS/RS). To get more news about Logistics Robotics, you can visit glprobotics.com official website.

The boom in logistics robots responds to the need to reduce costs and optimize processes to improve competitiveness. As opposed to conventional equipment, logistics robots ensure maximum throughput 24/7 if required, in addition to the safety of the goods, the operators, and all other elements involved in the warehouse.

What are logistics robots?

Logistics robots encompass any autonomous system or machine used to automate product flows, maximize safety, and boost productivity in warehouse operations.

The implementation of new technologies in any warehouse process — e.g., goods receipt, storage, stock management, order processing, and shipping — has led to these robots becoming more prominent. These solutions work with full autonomy to perform functions such as transferring products between two points, preparing orders, and storing products on racks.

More and more businesses are considering the introduction of robots in their logistics tasks to eliminate the risk of mistakes and ramp up productivity. This is reflected in the recent McKinsey study Automation has reached its tipping point for omnichannel warehouses, which puts the annual growth rate for the warehouse automation market at 23%, reaching $51 billion by 2030.

Which robots can be used for logistics?

In logistics automation, different machines and robots are employed to streamline processes, reduce logistics costs, and minimize the risk of accidents. Depending on the operations performed, the following robots can be used:

Goods receipt and dispatch. Product receipt and dispatch tasks can be carried out with logistics robots such as automatic truck loading and unloading systems, which make it possible to insert and remove pallets from trucks autonomously and with minimal operator intervention. Automatic conveyors for boxes and pallets can also be used to speed up goods receipt and dispatch, two key warehouse processes with the highest number of daily movements.

Storage robots. This category features stacker cranes — for both boxes (miniload) and pallets — which stand out for their capacity and agility when storing and retrieving items from the racks. There are several types of stacker cranes, including single-mast, twin-mast, and AS/RS trilateral stacker cranes. These logistics robots move horizontally and vertically in the storage aisles, inserting and removing pallets from the racks automatically. Businesses with a high volume of goods inflows and outflows can also opt for another very common automated solution: the automated Pallet Shuttle. With this compact storage system, an electric shuttle glides inside the storage channels, expediting pallet loading and unloading.

Order picking. AS/RS for boxes exemplify the concept of logistics robots in order preparation. A single storage solution can include both a stacker crane for boxes and a conveyor for boxes; with this configuration, the operators remain at their pick stations, preparing orders according to the goods-to-person method. Another option to facilitate picking are industrial robotic arms, tasked with performing pick and place, i.e., removing products from one location to place and organize them in another.

Internal goods movements. Logistics robots such as box and pallet conveyor systems are one of the most effective solutions for facilitating movements of goods in the warehouse because they make it possible to build very varied configurations to connect the various zones in the facility. Another conveying system used to link different areas in the warehouse are electrified monorails. Driven by an electric motor, these automatic trolleys move along an electrified rail suspended from the ceiling or fixed to the floor of the warehouse. Lastly, companies also turn to automatic guided vehicles (AGVs) or autonomous mobile robots (AMRs) to transport goods between the various working areas.

Transportation. Drones have recently touched down in the logistics sector. Their technology enables them to transport and deliver customer orders by air. Although still being tested, this solution would bring advantages such as lower costs, faster order deliveries (compared to conventional distribution by truck), less highway traffic, and as a result, a significant reduction in pollution. This type of delivery would be especially useful in urban areas. But also has great potential in remote and isolated rural areas.

Archives

- All

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021