Industrial videoscope being touted as the new ‘gold standard’ from freeamfva's blog

Industrial videoscope being touted as the new ‘gold standard’

Catastrophic failure of machinery or structures is usually expensive to repair and can pose a threat to the health and safety of workers and the public.To get more news about video borescope, you can visit seesemborescopes.com official website.

Remote Visual Inspection (RVI) of materials, components and structures can give inspectors and technicians warnings of many potential failures before they cause problems.

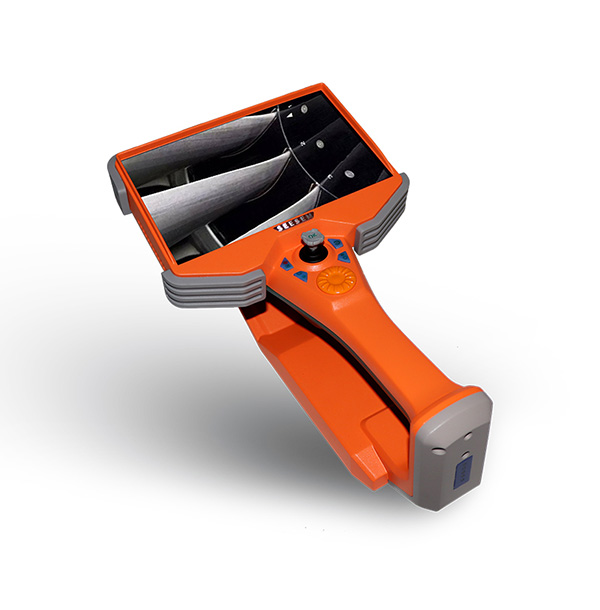

A videoscope is an inspection instrument that consists of a small camera mounted on a length of cable that permits inspection of internal surfaces and other features of an engine, machinery or structure without causing damage to delicate parts or the need to dismantle.

Olympus—a leading manufacturer of optical, electronic and precision engineering products has been at the forefront of videoscope development for many decades and with the introduction of the iPlex NX industrial videoscope, the company enters a new era of precision with a unit that has the greatest measurement accuracy on the market allowing the detection of the smallest defects.

“The NX can be used for a broad range of applications and is the new ‘gold standard’ for videoscopes,” said Brendan Slaven, Product Specialist – RVI at Olympus. “This latest unit gives you the best of everything.” An iPlex NX can help locate flaws that were previously undetectable, as well as streamline inspections in even the most difficult-to-reach areas.

The scope combines an industry-leading high-pixel CCD chip, an ultra-bright laser diode light system delivered through the tip of the probe, and Olympus’ unique PulsarPic processor to automatically adjust light output, to deliver the clearest images possible in changeable inspection conditions.

According to Slaven, the iPlex NX has the highest resolution of any scope on the market. “The new design and other enhancements mean that the NX can accurately measure areas up to four times larger than conventional scopes,” he said.

The iPlex NX also offers a unique multi Spot-Ranging function that enables real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides real-time surface shape information with no pause or break in the inspection. The videoscope camera can be controlled remotely by an operator while it is inserted in the cavity to be inspected.

Olympus’ pioneering TrueFeel electric articulation has been enhanced with reduced mechanical lag and greater sensitivity giving the NX ultra-responsive articulation and an increased range of motion in four directions.

“The NX is also the first high-end scope with a touch screen interface,” Slaven added. “You have the choice between the touch screen or Olympus’s ergonomically designed manual controls to suit the environment and inspection application.”

The touch screen is manoeuvrable for optimised ergonomics and viewing comfort allowing for more than a dozen commonly used functions to be changed with a single touch. The NX videoscope can be configured for a variety of inspection tasks, with 6.0 mm probes ranging in length from 3.5m to 7.5m and 4.0mm probes with lengths of 3.5m and 5m.

The finer probe tip allows access to very confined spaces such as between heat exchanger tubes or turbine blades. The compact and robust construction of the NX design has achieved International Protection Rating of IP55 and complies with stringent US military standards for dust and rain resistance, as well as drop testing.

The 8.4-inch display screen has an anti-reflective daylight-view monitor, allowing accurate inspections even in direct sunlight. The smaller size makes the iPlex NX ideal for locations with limited operator access including boilers, aeroplane fuselages and engines, and wind turbine gearboxes.

Post-inspection tasks such as archiving and reporting are simplified as operators can quickly recall and give titles to captured images from the NX display console. Olympus’ optional InHelp data management and reporting software automatically saves images in folders organised by inspection location.

Diagnostic information can easily be added to specific images using a couple of button clicks during the inspection, which saves valuable time back in the office. If changes need to be made or results queried, images and video data—including measurements, comments and other annotations—can be edited at any stage on a PC for reporting purposes.

A videoscope is an inspection instrument that consists of a small camera mounted on a length of cable that permits inspection of internal surfaces and other features of an engine, machinery or structure without causing damage to delicate parts or the need to dismantle.

Olympus—a leading manufacturer of optical, electronic and precision engineering products has been at the forefront of videoscope development for many decades and with the introduction of the iPlex NX industrial videoscope, the company enters a new era of precision with a unit that has the greatest measurement accuracy on the market allowing the detection of the smallest defects.

“The NX can be used for a broad range of applications and is the new ‘gold standard’ for videoscopes,” said Brendan Slaven, Product Specialist – RVI at Olympus. “This latest unit gives you the best of everything.” An iPlex NX can help locate flaws that were previously undetectable, as well as streamline inspections in even the most difficult-to-reach areas.

The scope combines an industry-leading high-pixel CCD chip, an ultra-bright laser diode light system delivered through the tip of the probe, and Olympus’ unique PulsarPic processor to automatically adjust light output, to deliver the clearest images possible in changeable inspection conditions.

According to Slaven, the iPlex NX has the highest resolution of any scope on the market. “The new design and other enhancements mean that the NX can accurately measure areas up to four times larger than conventional scopes,” he said.

The iPlex NX also offers a unique multi Spot-Ranging function that enables real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides real-time surface shape information with no pause or break in the inspection. The videoscope camera can be controlled remotely by an operator while it is inserted in the cavity to be inspected.

Olympus’ pioneering TrueFeel electric articulation has been enhanced with reduced mechanical lag and greater sensitivity giving the NX ultra-responsive articulation and an increased range of motion in four directions.

“The NX is also the first high-end scope with a touch screen interface,” Slaven added. “You have the choice between the touch screen or Olympus’s ergonomically designed manual controls to suit the environment and inspection application.”

The touch screen is manoeuvrable for optimised ergonomics and viewing comfort allowing for more than a dozen commonly used functions to be changed with a single touch. The NX videoscope can be configured for a variety of inspection tasks, with 6.0 mm probes ranging in length from 3.5m to 7.5m and 4.0mm probes with lengths of 3.5m and 5m.

The finer probe tip allows access to very confined spaces such as between heat exchanger tubes or turbine blades. The compact and robust construction of the NX design has achieved International Protection Rating of IP55 and complies with stringent US military standards for dust and rain resistance, as well as drop testing.

The 8.4-inch display screen has an anti-reflective daylight-view monitor, allowing accurate inspections even in direct sunlight. The smaller size makes the iPlex NX ideal for locations with limited operator access including boilers, aeroplane fuselages and engines, and wind turbine gearboxes.

Post-inspection tasks such as archiving and reporting are simplified as operators can quickly recall and give titles to captured images from the NX display console. Olympus’ optional InHelp data management and reporting software automatically saves images in folders organised by inspection location.

Diagnostic information can easily be added to specific images using a couple of button clicks during the inspection, which saves valuable time back in the office. If changes need to be made or results queried, images and video data—including measurements, comments and other annotations—can be edited at any stage on a PC for reporting purposes.

A videoscope is an inspection instrument that consists of a small camera mounted on a length of cable that permits inspection of internal surfaces and other features of an engine, machinery or structure without causing damage to delicate parts or the need to dismantle.

Olympus—a leading manufacturer of optical, electronic and precision engineering products has been at the forefront of videoscope development for many decades and with the introduction of the iPlex NX industrial videoscope, the company enters a new era of precision with a unit that has the greatest measurement accuracy on the market allowing the detection of the smallest defects.

“The NX can be used for a broad range of applications and is the new ‘gold standard’ for videoscopes,” said Brendan Slaven, Product Specialist – RVI at Olympus. “This latest unit gives you the best of everything.” An iPlex NX can help locate flaws that were previously undetectable, as well as streamline inspections in even the most difficult-to-reach areas.

The scope combines an industry-leading high-pixel CCD chip, an ultra-bright laser diode light system delivered through the tip of the probe, and Olympus’ unique PulsarPic processor to automatically adjust light output, to deliver the clearest images possible in changeable inspection conditions.

According to Slaven, the iPlex NX has the highest resolution of any scope on the market. “The new design and other enhancements mean that the NX can accurately measure areas up to four times larger than conventional scopes,” he said.

The iPlex NX also offers a unique multi Spot-Ranging function that enables real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides real-time surface shape information with no pause or break in the inspection. The videoscope camera can be controlled remotely by an operator while it is inserted in the cavity to be inspected.

Olympus’ pioneering TrueFeel electric articulation has been enhanced with reduced mechanical lag and greater sensitivity giving the NX ultra-responsive articulation and an increased range of motion in four directions.

“The NX is also the first high-end scope with a touch screen interface,” Slaven added. “You have the choice between the touch screen or Olympus’s ergonomically designed manual controls to suit the environment and inspection application.”

The touch screen is manoeuvrable for optimised ergonomics and viewing comfort allowing for more than a dozen commonly used functions to be changed with a single touch. The NX videoscope can be configured for a variety of inspection tasks, with 6.0 mm probes ranging in length from 3.5m to 7.5m and 4.0mm probes with lengths of 3.5m and 5m.

The finer probe tip allows access to very confined spaces such as between heat exchanger tubes or turbine blades. The compact and robust construction of the NX design has achieved International Protection Rating of IP55 and complies with stringent US military standards for dust and rain resistance, as well as drop testing.

The 8.4-inch display screen has an anti-reflective daylight-view monitor, allowing accurate inspections even in direct sunlight. The smaller size makes the iPlex NX ideal for locations with limited operator access including boilers, aeroplane fuselages and engines, and wind turbine gearboxes.

Post-inspection tasks such as archiving and reporting are simplified as operators can quickly recall and give titles to captured images from the NX display console. Olympus’ optional InHelp data management and reporting software automatically saves images in folders organised by inspection location.

Diagnostic information can easily be added to specific images using a couple of button clicks during the inspection, which saves valuable time back in the office. If changes need to be made or results queried, images and video data—including measurements, comments and other annotations—can be edited at any stage on a PC for reporting purposes.

A videoscope is an inspection instrument that consists of a small camera mounted on a length of cable that permits inspection of internal surfaces and other features of an engine, machinery or structure without causing damage to delicate parts or the need to dismantle.

Olympus—a leading manufacturer of optical, electronic and precision engineering products has been at the forefront of videoscope development for many decades and with the introduction of the iPlex NX industrial videoscope, the company enters a new era of precision with a unit that has the greatest measurement accuracy on the market allowing the detection of the smallest defects.

“The NX can be used for a broad range of applications and is the new ‘gold standard’ for videoscopes,” said Brendan Slaven, Product Specialist – RVI at Olympus. “This latest unit gives you the best of everything.” An iPlex NX can help locate flaws that were previously undetectable, as well as streamline inspections in even the most difficult-to-reach areas.

The scope combines an industry-leading high-pixel CCD chip, an ultra-bright laser diode light system delivered through the tip of the probe, and Olympus’ unique PulsarPic processor to automatically adjust light output, to deliver the clearest images possible in changeable inspection conditions.

According to Slaven, the iPlex NX has the highest resolution of any scope on the market. “The new design and other enhancements mean that the NX can accurately measure areas up to four times larger than conventional scopes,” he said.

The iPlex NX also offers a unique multi Spot-Ranging function that enables real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides real-time surface shape information with no pause or break in the inspection. The videoscope camera can be controlled remotely by an operator while it is inserted in the cavity to be inspected.

Olympus’ pioneering TrueFeel electric articulation has been enhanced with reduced mechanical lag and greater sensitivity giving the NX ultra-responsive articulation and an increased range of motion in four directions.

“The NX is also the first high-end scope with a touch screen interface,” Slaven added. “You have the choice between the touch screen or Olympus’s ergonomically designed manual controls to suit the environment and inspection application.”

The touch screen is manoeuvrable for optimised ergonomics and viewing comfort allowing for more than a dozen commonly used functions to be changed with a single touch. The NX videoscope can be configured for a variety of inspection tasks, with 6.0 mm probes ranging in length from 3.5m to 7.5m and 4.0mm probes with lengths of 3.5m and 5m.

The finer probe tip allows access to very confined spaces such as between heat exchanger tubes or turbine blades. The compact and robust construction of the NX design has achieved International Protection Rating of IP55 and complies with stringent US military standards for dust and rain resistance, as well as drop testing.

The 8.4-inch display screen has an anti-reflective daylight-view monitor, allowing accurate inspections even in direct sunlight. The smaller size makes the iPlex NX ideal for locations with limited operator access including boilers, aeroplane fuselages and engines, and wind turbine gearboxes.

Post-inspection tasks such as archiving and reporting are simplified as operators can quickly recall and give titles to captured images from the NX display console. Olympus’ optional InHelp data management and reporting software automatically saves images in folders organised by inspection location.

Diagnostic information can easily be added to specific images using a couple of button clicks during the inspection, which saves valuable time back in the office. If changes need to be made or results queried, images and video data—including measurements, comments and other annotations—can be edited at any stage on a PC for reporting purposes.

Post

| By | freeamfva |

| Added | Mar 26 '23 |

Tags

Rate

Archives

- All

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

The Wall